For decades, racers and tuners have always sought ways to extract as much power from an engine as possible. Most of the time adding power is a matter of getting more air and fuel into the engine, but what if Here at STILLEN, we’ve been developing high performance products for a variety of makes and models since the early 80’s.

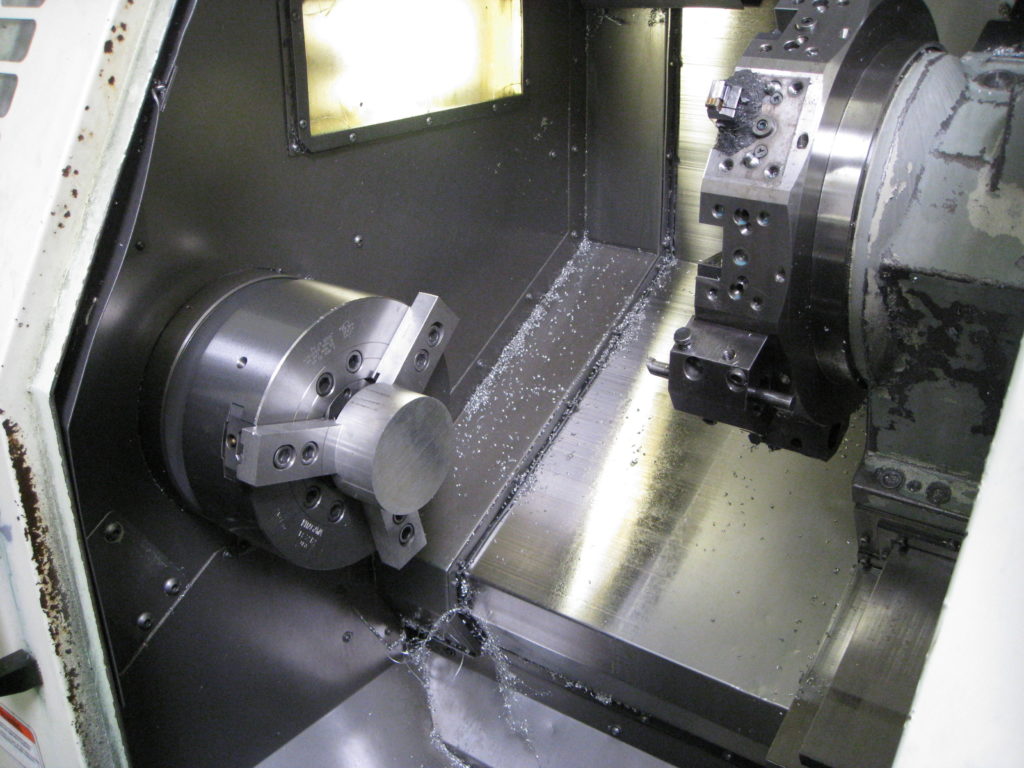

After a few years of frustrations with outside vendors and outside machine shops, STILLEN invested in an in-house CNC machine shop to “do it ourselves”, and we’ve never looked back.

With in-house CNC lathes and CNC mills, STILLEN is able to control every aspect of their products. From the material selections and quality, to the machining accuracy and consistency all the way down to the plating and finishing processes STILLEN controls each detail so we can be 100% confident in the quality of our product from start to finish.

For many years STILLEN carried other manufacturers pulleys and were able to learn what to do and most importantly, what not to do.

The line of STILLEN lightweight pulleys and complete pulley sets is the combination of decades of that experience combined with STILLEN’s expertise in CNC machining.

What Is A Lightweight Pulley or Underdrive Pulley?

The simplest answer to this is that they are exactly what their name implies. From the factory your vehicle comes with a cast-iron pulley or steel crank pulley. There is nothing wrong with this other than the fact that it is not optimized for vehicle performance. Anything that spins takes power to spin it. This means that a heavy cast iron or steel pulley is going to take more power to spin than a lighter weight pulley constructed out of billet aluminum and machined to reduce as much rotating mass as possible.

Underdrive pulleys are designed to slow down the rotation of the surrounding accessory pulleys such as alternator, air conditioning etc. By slowing down the rotation of these pulleys it further reduces the amount of work the engine is having to perform. The less accessory work you make the engine do the more power can be transferred to the rest of the drivetrain, thus ultimately reaching the tires. We like to say that lightweight or underdrive pulleys do not actually “make” horsepower. They recover power that was lost due to the excess power the engine had to put out simply to rotate those pulleys.

Why Are They Important?

Lightweight and/or underdrive pulleys are a great way to make your engine run more efficiently and with less resistance. Whether developing a performance vehicle for the street or for the track one of the most important things to keep in mind is efficiency. How can you make the vehicle run as efficiently as possible? One of the best ways to improve the performance of a vehicle is to reduce the weight of any rotating mass. Whether you’re reducing the weight of wheels and tires, rotors, flywheels, or crank pulleys you are effectively transferring more of that regained power to the tires and therefore to the road.

Aside from the increase in rear wheel horsepower we’ve had, customers tell us they’ve noticed that the engine revs quicker, feels like it’s been freed up and is less restrained. Some customers also report an increase in fuel economy as the engine is running more efficiently and does not have as much weight to spin.

How Are STILLEN Pulleys Different?

As we mentioned earlier, before embarking on the STILLEN line of high performance pulleys the engineers at STILLEN sat down and discussed all of the things we’ve learned from our decades of experience and what we wanted our pulleys to be.

We have seen where other manufacturers pulleys were improperly machined and/or improperly balanced or the factory timing marks were not machined correctly in relation to the crankshaft keyway. All of these things and more are huge factors in the performance of a crank pulley and need to be taken into consideration when developing the crank pulleys and associated accessory pulleys.

To start with all STILLEN pulleys are designed in our 3D CAD software. Once the initial design is completed the parts are rendered in our FEA (finite element analysis) software. This software will simulate loading the parts with forces higher than what they will see in real world situations. By doing this we are able to see the weak points of the design and at what forces the part will fail. Once we know that our design exceeds the real world forces this part will see it will be approved for production.

Some pulleys, primarily crank pulleys, also need to be finished with precise timing marks that need to be correctly machined in relation to the crank keyway. It is extremely important to do this process accurately as this will make the car run improperly if these timing marks are not accurately machined.

Finally, the crank pulleys are finished with a 304 stainless steel sleeve used for main seal contact points just like the factory pulleys.

To speak with an expert and find out more about our full line of STILLEN lightweight aluminum pulleys, give us a call at (866) 250-5542. You can also visit STILLEN and check out the entire range of performance pulleys we offer.

Up to 80% lighter weight than stock steel and up to 10% lighter than other aftermarket pulleys, we’ve seen power gains of up to 10+ HP at the wheels.

Both underdrive and stock diameter applications available for most popular Nissan / Infiniti vehicles. – See more at: http://www.stillen.com/product/pulleys/stillen-standard-performance-lightweight-crank-pulley-400340-8117.html#sthash.4xvNEuhb.dpuf