Brake Systems 201: Upgrading the OEM Brakes with Rotors, Pads, Lines & Fluids

By Richard Fong

In our Brakes 101 edition of STILLEN U, we took a look at the basics of the automotive brake system and how your car’s brake system works. Now that you’ve gotten familiar with some of the first and most straightforward brake upgrades in our Brake Systems 101: Pads and Rotors, it’s time to look at the next modifications in line to optimize the factory brake system. In this edition, Brake System 201, we’ll take a look at how upgrades like 2-Piece Brake Rotors, Fluids and Performance Braided Stainless Brake Lines can further improve your factory brake system for greater performance on both the street and the track.

The important thing to remember here is that Brakes, like tires, are a wear item, and that means you’re going to have to buy replacement brake parts no matter what, whether you’re just daily-driving or running an autocross campaign. While the factory equipment is generally adequate for an everyday street use, it is often less-than-ideal for high-performance driving. It’s also worth noting that with today’s generation of performance cars incorporating hybrid tech, for example, it may not be possible to install a Big Brake Kit on a hybrid vehicle with features like Regenerative Braking. However, that said, upgraded rotors, pads, lines and fluids are still an option for increasing braking performance while retaining functionality.

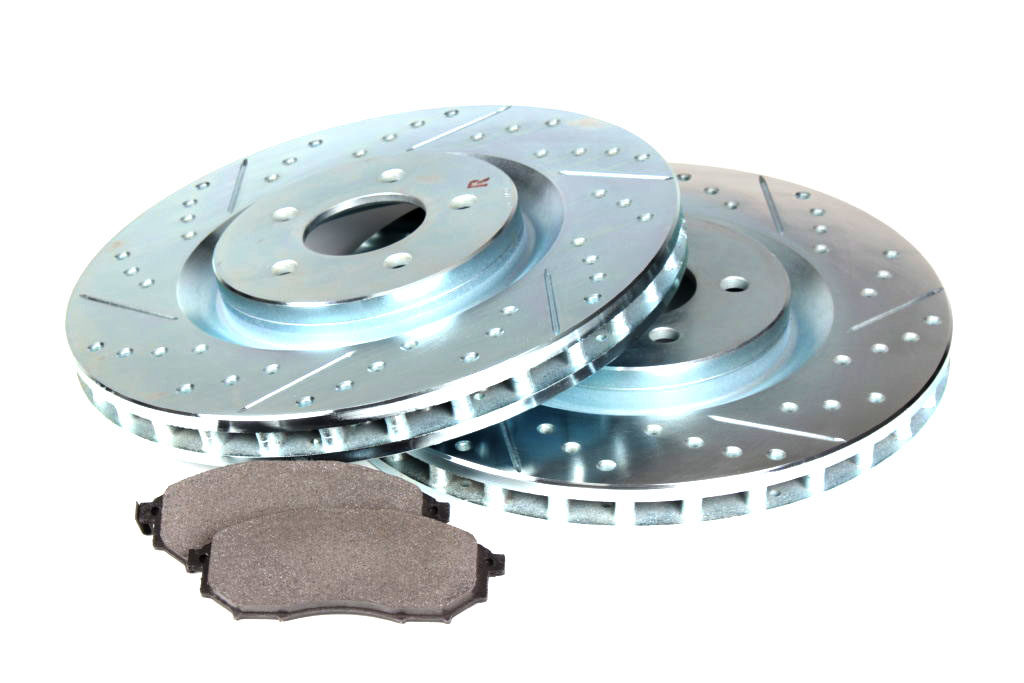

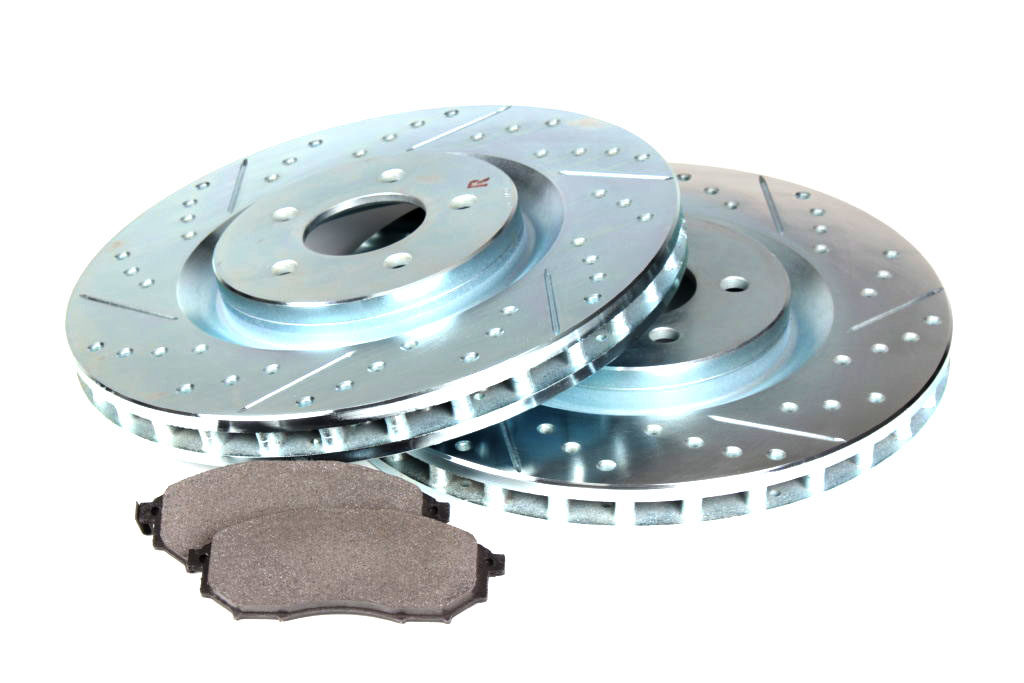

Upgrading brake pads and rotors can make a considerable improvement to a vehicle’s braking performance, and the cost is often around the same price as stock replacement parts (and sometimes can be less expensive than the stock part), making this a great upgrade for enthusiasts who daily drive their ‘fun’ car.

Picking The Right Brake Pad Compound for the Way YOU Drive

Each pad type and compound is optimized depending on your vehicle’s intended purpose- a luxury car will likely have pads designed for low dust and quiet, smooth operation, and a performance oriented vehicle might come with oversize semi-metallic brakes that often squeak but offer fantastic stopping power. There are a plethora of High Performance OE Replacement Brake pads available from STILLEN, DBA Brakes and Hawk Performance to name a few, and these pads are offered in a variety of friction compounds ranging from organic and ceramic to semi-metallic to suit a variety of different driving demands. Each compound has its own pros and cons.

As we mentioned in our discussion of Brake Pads in Brakes 101, the operating temperature range of your brake pad’s compound has a significant impact on how it performs under aggressive, hard use, such as racing- as well as how it handles crawling freeway stop and go traffic. As we explained in Brakes 101, the demands of racing are totally different than the demands of street driving – that means you can’t just throw “RACE” pads on and drive around town, because a race brake pad is designed to perform well in a much higher temperature range than your street-spec OEM pads. While your OEM pads might not work once you get them too hot, conversely, race pads won’t work when they’re too cold, such as when you first start driving, or get off the freeway after driving at speed for a while.

Balancing Street Performance & Track Day Fun

With all of that in mind, it might seem like an impossible task to balance street performance with the needs of a track day without going to an all-out big brake kit. However, that’s not the case- As we mentioned in Stillen U: Brakes 101, there are a few upgradeable parts that can significantly enhance the performance of your car’s factory-design brake system before making the jump to aftermarket calipers and larger rotors. Many manufacturers, like AP Racing, STILLEN, DBA Brakes and HAWK Performance for example, offer a high performance replacement for the OEM rotors, pads and lines which provide a marked improvement in braking performance without the expense of a full on Big Brake Kit.

It’s More Affordable Than You Think

Many enthusiasts are scared off by the sticker shock of a big brake kit’s average cost, so one might think performance replacement parts would be equally pricey, but not so. Funnily enough, performance aftermarket replacements for the OEM brake rotors and pads can often be less expensive than the OEM parts typically cost at a dealer or brake shop.

As we’ve already said, you’re going to have to buy new brakes no matter what you do. The cost is likely around the same as the non-performance replacement parts, if not cheaper – and it takes the same amount of effort to install an upgraded replacement as it is to pop in another set of stock brake components. Taking that into consideration, upgrading your OEM design brakes with performance replacement parts is a no brainer.

Know When To Service Your Brakes – Watch out for Bad Vibes

A smoothly-operating vehicle typically indicates that all is well and functioning properly. When an ABS-like vibration feeds back through the brake pedal, it can be disconcerting to some and annoying to others. In either case, it’s certainly an indication of something amiss that requires attention. That vibration could simply be caused by uneven pad material built up on the surface of the rotor, for which a proper brake service (new pads, resurfaced or replaced rotors, brake fluid flush) would remedy. However, in the case of performance and heavy utility applications, the damage to the rotors could be more severe, so be cognoscente of the feedback you get from your brakes and don’t procrastinate on checking out vibration issues.

Getting Rid of Your Car’s Achilles’ Heel

Beyond the fact that the cost of Performance Replacement Brake Rotors & Performance Brake Pads from AP Racing and other aftermarket brakes are often comparable to the cost of ‘stock’ brakes, it’s also worth saying that the brake systems of certain cars can get overwhelmed VERY quickly, making an otherwise controllable, predictable sportscar into something dangerous.

As we mentioned in Brakes 101, Brake Fade is the gremlin you’re fighting against when trying to get more out of your brakes, and brake fade sets in as your brakes get too hot. As the rotor and pad exceed their heat limits, the pad’s friction compounds don’t work anymore, and as the calipers get heatsoaked, the brake fluid boils.

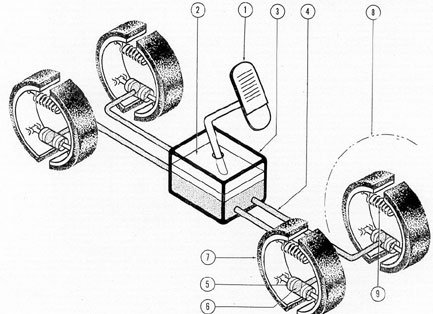

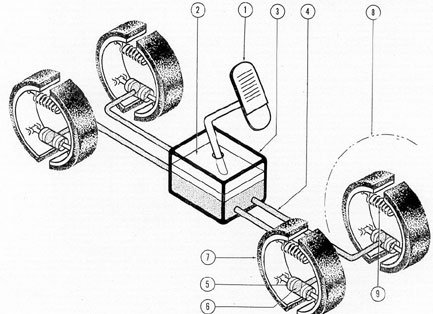

Pushing down on the pedal pushes down on the fluid, and that force engages the brakes.

The system depends on the incompressibility of the hydraulic fluid to work. Air is compressible, and that void in the lines will prevent effective hydraulic system function. (Concept Illustration via Wikipedia Commons)

Bubbles Are Bad

When the brake fluid boils, the rubber brake lines expand as bubbles form in the boiling fluid, causing braking to become spongy and unresponsive. Since the hydraulic system cannot effectively exert pressure on the calipers due to all the heat-induced expansion, and so the brakes lose much of their stopping power. On a racetrack, brake fade could be the difference between making the next turn and kissing the Armco barriers.

Unfortunately, accidents caused by overwhelmed and overheated brake systems aren’t just wild hyperbole and conjecture – they’re very much a reality. One such example of an under-performing, fade-prone brake system is a platform we’re very familiar with here at STILLEN – the Nissan 370Z, and 350Z as well, though the 350 isn’t quite as bad. Let us be clear, they’re by no means the only vehicles suffering from braking issues, but for the purposes of this discussion, they’re a great example. The 370Z in particular is notorious for brakes that quickly overheat and fade badly after only a few laps of hard trackday driving, or say, a 10/10ths canyon run – a flaw which caused one automotive magazine to crash the 370Z they were reviewing into the wall at VIR. Ouch.

In the cases like these, upgrading to better brake pads paired with more efficiently cooled Brake Rotors, in addition to replacing the OEM rubber brake lines with Stainless Steel Braided Brake lines helps correct this potentially dangerous shortcoming.

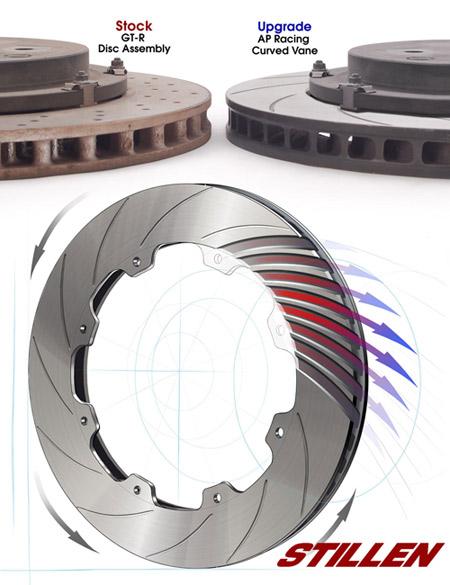

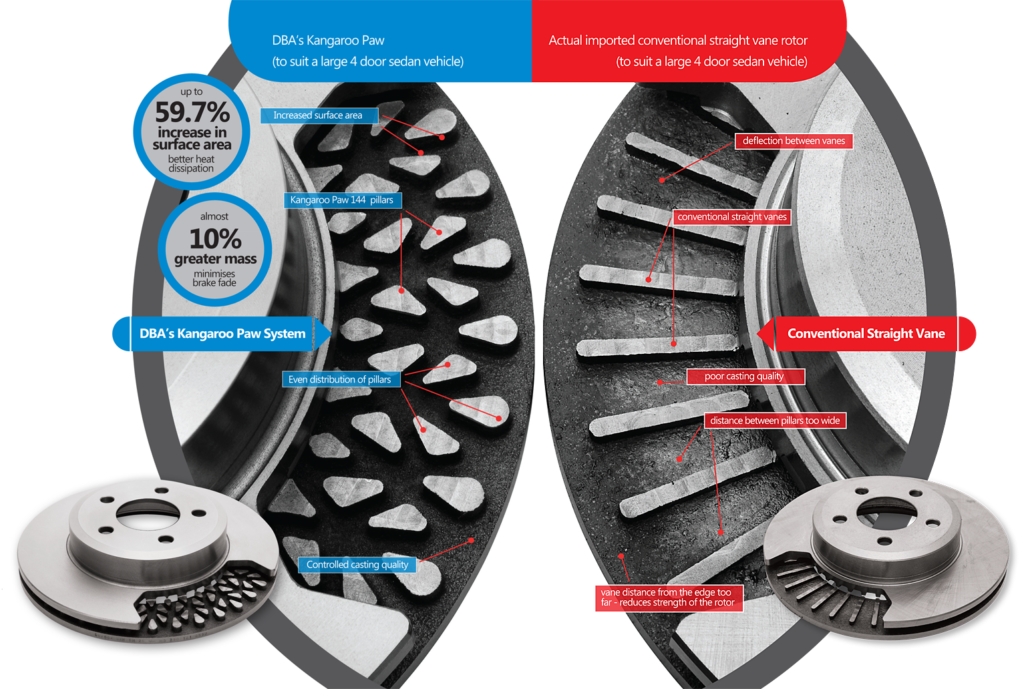

One option is 2-Piece Vented Rotors, such as those offered by AP Racing, STILLEN and DBA Brakes to name a few examples. These 2-piece OEM replacement rotors offer dramatically improved airflow, which enhances thermal transfer for better cooling, while more aggressive pads offer better bite and shorter stopping distance, and the Braided Stainless Brake Lines eliminate the expansion problems of rubber brake lines. Last but not least, replacing old, dirty brake fluid with fresh high-temperature Racing Brake Fluid raises the boiling point of your brake fluid, helping to make spongy, faded brakes a thing of the past.

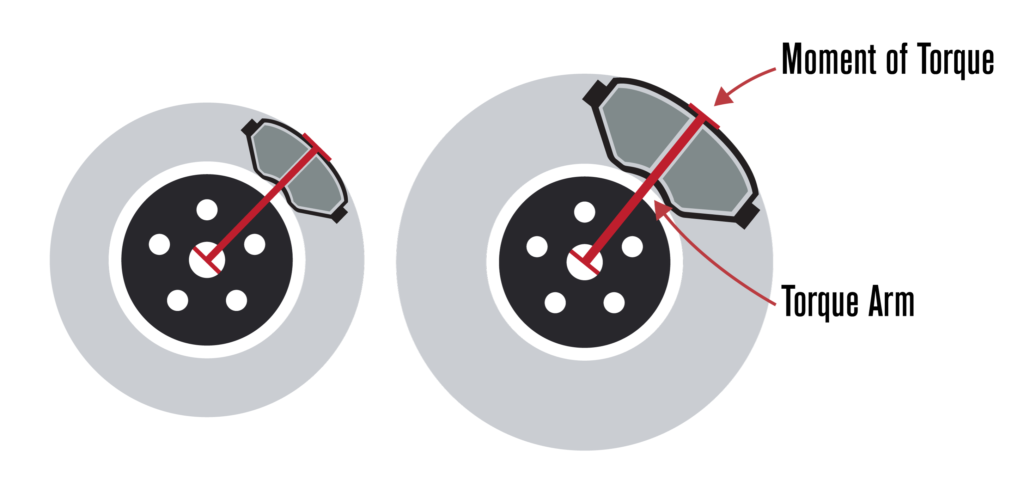

The Big Advantage of 2-Piece Rotors: Superior Heat Dissipation

A vast majority of brake rotors on the market are manufactured as a single piece of iron for cost and durability. As the friction surface for the pads, your rotors are subjected to extreme heating and cooling cycles. Since the center or “hat” of the rotor bolts to the wheel hub, it is sandwiched between the hub and the mounting pad of the wheel. The force of the wheel pinning the rotor against the hub limits the rotor’s ability to expand and contract freely when subjected to the heavy thermal loads created by extreme braking conditions (as would be the case on a racetrack or during an aggressive mountain drive). Preventing and limiting this expansion could lead to warped rotors.

A viable solution is upgrading to a OE replacement 2-Piece Brake Rotor. In a 2-piece rotor, a billet aluminum hat is fastened by way of “floating” hardware to the brake rotor disc, which allows the rotor to expand and contract to effectively dissipate heat without being restricted by the hat.

A 2-piece rotor also permits the use of exotic lightweight rotor materials as well, like a carbon-ceramic matrix. An added benefit to having a billet aluminum hat and/or lighter rotors is that they offer reduced unsprung weight. This reduction in ‘unsprung weight’ helps to sharpen and lighten steering response which further lends to improved handling.

Two piece replacement rotors are definitely the better option as performance replacement rotors go, however, if 2-piece rotors are too spendy, you can still improve over stock with a set of drilled or slotted 1-piece rotors. The improvement is less dramatic when opting for 1pc over 2pc, but it’s still better than stock.

In many cases, just upgrading the brake components themselves goes a long way to stave off brake fade, but sometimes that’s not enough. In some mof those cases, the brake heat issues are exacerbated by poor ventilation. In the case of the 370Z, we offer a Brake Cooling Kit to correct this. These brake ventilation kits further help fight brake fade by adding a set of ducts to route cool air directly to the inside of the rotor, improving its ability to shed heat quickly – this is important, as just venting cooler air at the rotor’s outside surfaces would be ineffective.

Don’t Forget The Performance Brake Fluid…

If you’ve upgraded your pads and rotors, but have not upgraded the brake fluid, this could cause poor braking performance, despite the other upgraded parts. The solution is to upgrade your brake fluid. You might have seen the term “DOT” used when people talk about brake fluid – this refers to the Department of Transportation (DOT), which has established standards to indicate a fluid’s capabilities. The name denotes the fluid’s heat capacity and performance capability as required by the DOT.

Boiling Point

A recurring theme in brake systems – and frankly, automotive performance in general – is that heat is the enemy, and managing heat effectively is what makes the difference between finishing and a DNF. For the most part, this is true, the exception being specialized brake pad compounds formulated to function optimally at higher temperatures (eg, racing brake pads such as those used on the NASCAR example earlier). Aside from this and other “special exceptions”, heat isn’t good for the car or its performance– and the heat that is generated by the friction between the rotors and the pad material eventually transfers to the calipers, then the brake fluid. And once the fluid boils, braking efficacy decreases dramatically, so fluid is more critical than you might think.

Street vehicles rarely exceed the capabilities of DOT 3 fluid under normal driving conditions, so as a result, DOT 3 brake fluid is the type most commonly used in automobiles. When brake fluid heats to the point of boiling, pockets of air form in the brake lines. Air, unlike hydraulic brake fluid, is compressible, and those air bubbles are compressible voids, which translates into a spongy brake pedal and an unresponsive brake system with dramatically reduced stopping ability. Under performance conditions such as on a track or a road requiring significant and frequent brake input, upgrading to DOT 4, DOT 5 or DOT 5.1 brake fluid will help to maintain the responsiveness and effectiveness of the brake’s hydraulic system.

DOT Standards

Typical factory brake fluid is engineered to function within a prescribed temperature range optimized for the majority of driving conditions that the manufacturer expects a vehicle to encounter. This covers a broad spectrum of conditions ranging from freezing to triple-digit ambient temperatures. While these requirements cover a seemingly broad range of temperatures, the brake fluid must endure far more extreme temperatures. DOT 3 fluid is the most common fluid type employed by automakers with some requiring DOT4 fluid (in the case of higher performance or heavy duty applications). DOT 3, 4 and 5.1 are polyethylene glycol based fluids while DOT 5 is silicone based. The hygroscopic traits (propensity to absorb moisture from the atmosphere) of the DOT 3, 4 and 5.1 fluids could render the fluids less effective over time. Regular flushing of the brake system mitigates this effect. The silicone-based DOT 5 fluid tends to cost more but benefits from its hydrophobic properties.

*DOT Performance Standards are not indicative of all Manufacturers’ Brake Fluid Performance.

Fluid Grade Dry Boiling Point Wet Boiling Point

DOT 3 401 F 284 F

DOT 4 446 F 311 F

DOT 5 500 F 356 F

DOT 5.1 500 F 356 F

Containing the Pressure

As we just said, brake fluid boils when it gets too hot, and when it boils, it creates air bubbles in the brake lines. Virtually all modern brake systems are hydraulic, which means that they rely on incompressible hydraulic fluid (in this instance, brake fluid) to create the force that pushes the pistons against the pads when the brake pedal is depressed. Hydraulic systems depend on the lines being free of air bubbles to be able to work and effectively slow the vehicle.

Typical OEM rubber brake lines tend to expand under hard driving conditions, resulting in slower response and a spongy pedal feel.

Most stock brake lines are high-pressure rubber hoses – and though we know of rubber’s shortcomings, the reason rubber is used is because the lines are designed to be flexible, so as to allow movement throughout the full range of travel for your suspension. For the majority of applications and the way most people drive, that’s fine. However, during high performance braking when they get too hot, these factory lines stretch and expand as extreme pressure of the boiling brake fluid creates air bubbles in the lines, resulting in a non-responsive, spongy brake pedal and dramatically reduced braking performance. This is why replacing rubber lines with stainless braided brake lines offers such significant improvement in pedal feel.

Performance brake lines (such as those offered by Goodridge) feature a PTFE liner (inner hose) that is shrouded by a flexible sheathing (stainless steel, most commonly) that protects the liner and prevents expansion. This keeps the fluids moving toward the calipers, preventing the mushy pedal feel that expanded rubber lines cause, delivering much more responsive braking and firmer brake pedal feel under all driving conditions.

Stainless-steel braided brake lines like this Goodridge unit feature a PTFE liner for durability. The braiding helps to protect the liner from abrasion while also mitigating the expansion of the line under pressure.

Easy Installation

If you’re concerned about keeping your vehicle ‘close to stock’ or the ability to easily reverse the modification, upgraded replacement brake components are a direct bolt-on part for your vehicle, and can be replaced with stock components again when they wear out. While removing a big brake kit isn’t terribly complicated, bolt on parts like this are easy to reverse, as both installation and removal are as straightforward as a standard brake job.

Maxed Out

Now that you’ve learned about the basics of brake systems, you can maximize the stopping performance of your vehicle. Slowing and stopping are paramount for safety as well as performance, regardless of your application. From streetcars and track cars to tow and utility vehicles, a good braking system is a must. If you’re pushing your vehicle beyond these bolt-on solutions, you could be a candidate for a big brake upgrade, which will be covered in the next two installments of STILLEN University. Stay on track!

In short, upgraded replacement brake parts offer much better braking performance at a fraction of the cost of an outright Big Brake Kit – with better-cooled brake rotors, a more aggressive brake pad and expansion-free stainless lines and high performance brake fluid, stopping power is improved and brake fade is kept at bay longer. Since these upgraded parts are often around the same price as stock replacement parts as well, that makes this bolt on brake upgrade a great option for the daily driver enthusiast, and in addition to better performance on track, upgraded brakes reduce your stopping distance, which increases your margin of safety, too.

If you’re pushing your vehicle beyond these bolt-on solutions, you could be a candidate for a big brake upgrade, which will be covered in the next two installments of STILLEN University.

Have questions about what combination would be right for your application and the way you drive? Reach out and give us a call at 866-250-5542 to speak to our knowledgeable staff, and if the phone’s not your thing, you can always email us at sales@stillen.com or use the live chat on stillen.com to help guide you to the brake product that best suits your needs, and we have a massive range of performance and replacement brake components in stock and readily available.

Contact:

866-250-5542

sales@stillen.com

Live Chat

stillen.com