See all the hard work and attention to detail STILLEN puts when manufacturing the Nissan Z Cat-Back Exhaust System.

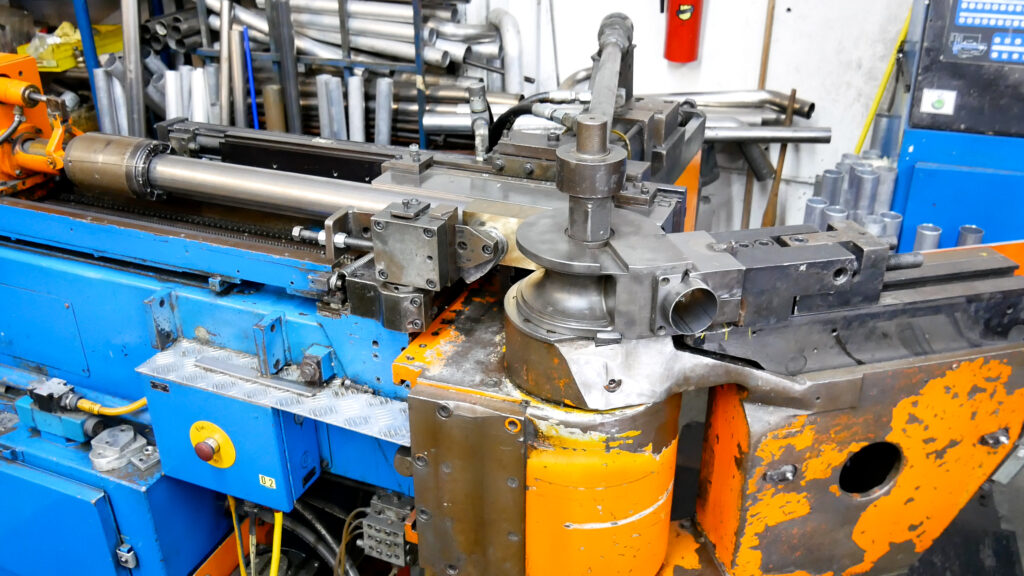

CNC Band Saw and Mandrel Tube Bender

To start with, 2.5-inch stainless steel tube is cut in bundles using the STILLEN hydraulic CNC controlled band saw. From the saw the tubes are processed on our CNC Mandrel Tube Benders. Every tube coming off the bender is verified in our proprietary bend check fixtures to ensure each tube meets our specifications.

CNC Milling Machine and STILLEN X Pipe Fixture

The STILLEN X pipe has been engineered for optimum performance and exhaust gas flow. To achieve the best performance possible the X pipe tubes are loaded into the CNC milling machine and are precision machined for perfect fitment into the weld fixture.

Once the machining process is finished the machined tubes along with the weld fixture are taken to the production welding booths where our craftsmen tig weld the tubes and braces to form a single X pipe.

When merging dual 2.5” exhaust tubes into a single tube, the equivalent size tube required is more than 4 inches in diameter. Because we cannot fit a 4-inch tube through the chassis and a true dual 2.5” exhaust did not sound good on this platform. We chose to merge the two banks for the best sound, but to do so in a way that allowed for optimal exhaust gas flow without causing a restriction.

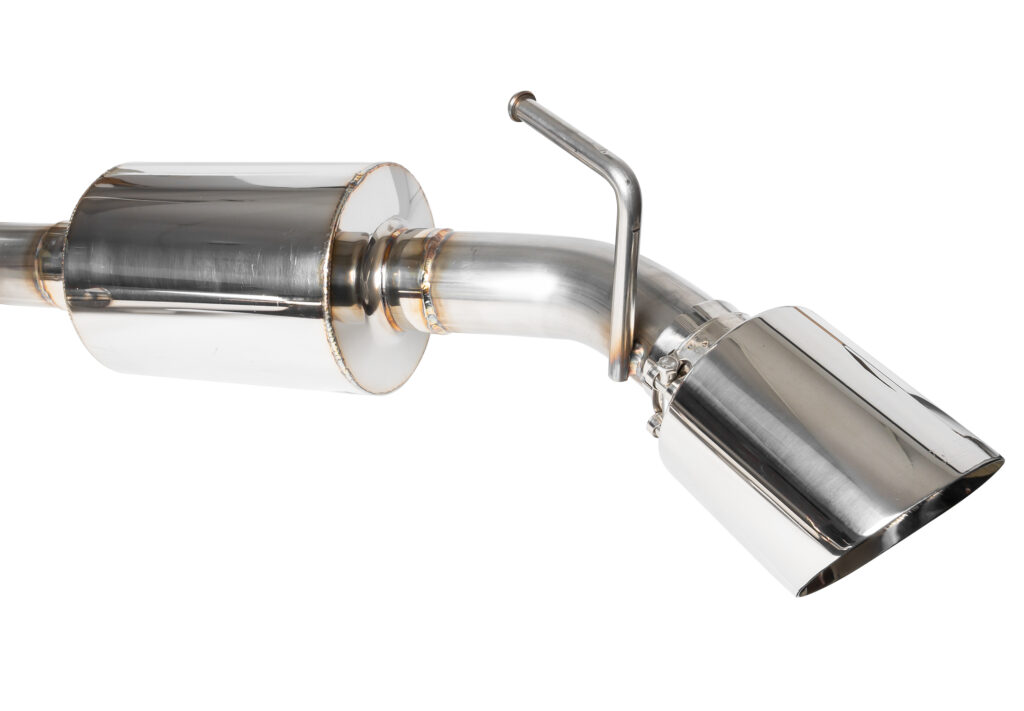

STILLEN Mufflers

To assemble the mufflers our production team begins by assembling the perforated tube inner core. Then form the end caps for the body of the muffler. The inner core and one side of the muffler is tack welded together then the muffler goes back to assembly to have the high temperature ceramic wool inserted.

Once completed the mufflers go back to welding. The outer cap is tacked back together. This is the only time where the exhaust system or any of its components leaves the STILLEN facility. The mufflers are sent to an outside processor for polishing before they’re finished welding.

STILLEN Proprietary Rotational Welding Positioner

After the mufflers return from polishing, it is placed on our proprietary rotational welding positioner. Our engineering team created this positioner so that our welders could accurately control the speed. Also the orientation of the mufflers to give a precision tig welded finish. The mufflers are purposely left with a fantastic “burn” finish to show the tig welded craftsmanship.

Final Welding and Assembly

Now we enter final welding and assembly. Every single exhaust system goes through our pre-assembled weld fixtures. These weld fixtures located all of the key components. The weld fixtures also align everything to ensure perfect, repeatable fitment on all of the various components.

For the 2023 Nissan Z, STILLEN proudly offers two different styles of exhaust systems. The “Street Series” Cat-Back Exhaust features the STILLEN mufflers. We also offer our “Competition Series” which doesn’t have any mufflers. The “Competition Series” Exhaust is intended to let the twin turbo V6 VR30 engine be heard!

We also offer 3 different tip options for the Nissan Z “Street Series” and “Competition Series” Cat-Back Exhaust System. STILLEN offers carbon fiber, brunt, and polished stainless steel.

Since 1986 STILLEN has been a leader in exhaust system manufacturing. STILLEN is dedicated to manufacture all our exhaust systems in the United States of America.