STILLEN INFINITI Q60 REDSPORT 400 SEMA 2017

STILLEN is excited to announce the launch of our complete line up of products for the 2018 INFINITI Q60 at the 2017 SEMA show.

The INFINITI Q60 redsport is a very exciting car as it brings performance back to the INFINITI marque. Featuring a potent 400 horsepower twin turbo V6 badged the “VR30.” This car offers the driver an exhilarating experience and inspires the driver to push the car aggressively.

STILLEN has been involved in performance parts for off-road trucks, supercars and street performance cars of a variety and makes and models, but STILLEN is perhaps best known for our experience in tuning NISSAN/INFINITI vehicles… we’ve been involved with developing performance parts for Nissan (and later Infiniti) for over 30 years now. When the opportunity came to work with Infiniti on this platform, we jumped at the chance and let our engineers run wild.

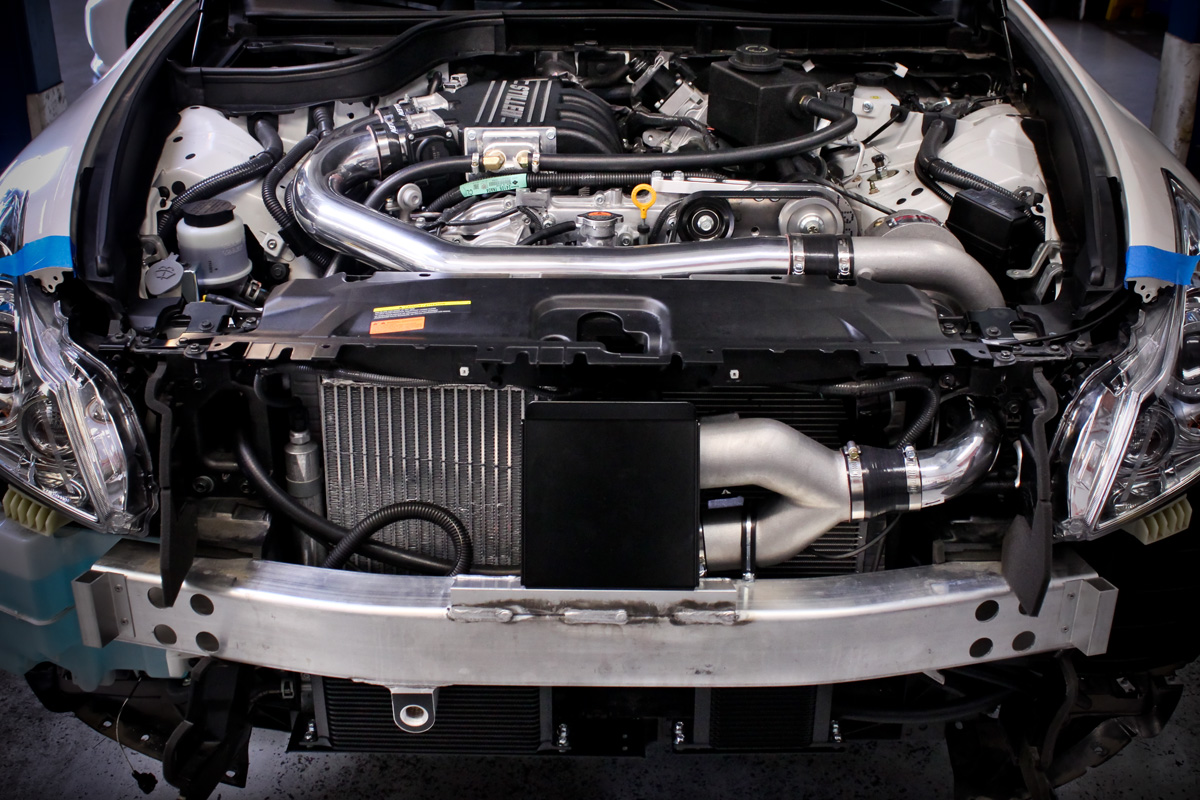

INTAKE

To kick things off, we took a look at how we could beef up the car’s performance. Our engineering team immediately began dissecting the air intake system to study it and determine how we could optimize airflow. While the engineering team was busy with figuring out how to get every last pony out of the intake, our fabrication team were hard at work under the car, reviewing the exhaust routing, tube diameter, configuration of the system and the construction of its muffler, all in order to see what gains could be made.

After going through more than 20 prototype intakes trying to achieve our goals, our induction specialists produced a Q60 Intake design that yielded a huge gain of over 20 horsepower at the wheels, and that’s without the need for further tuning or any modifications to the vehicle. Not every ‘high flow’ intake on the market works with the OEM ECU map, so making sure our intakes benefit the car with the stock tune is a high priority for our design team. The end result is what you see above – the urethane airboxes offer a significant advantage over an exposed conical filter, as the airboxes ensure that the intakes are drawing in only cool, outside air, rather than sucking in hot air from inside the engine bay (which robs you of power). Designed as a complete solution, the STILLEN Cold Air Intake for 2017 Infiniti Q60 comes complete with silicone couplers, CNC machined and tig welded aluminum MAF tubes as well as poly-urethane air boxes to keep the engine fed with cooler air, helping to deliver maximum power output.

EXHAUST

Turbo V6 engines are notoriously difficult to get the sound “just right.” In the end, our team was not satisfied with any of the common mufflers we could source “off the shelf.” The only option was to build our own. So, we engineered our own mufflers, manufactured them in house, and pack them with a high temperature ceramic wool. These tuned mufflers truly allow the heartbeat of the car to be experienced. The final exhaust design was selected after 15 different prototype systems were rigorously tested on our Dynojet chassis dyno. It took quite a while to determine what the engine wanted in order to produce the most power across the entire powerband. The end result is a tuned Y-Pipe, leading to a single Mid-Pipe which branches back into a dual outlet exit.

BODYSTYLING

With the performance parts development underway, now it was time to address the exterior styling. The Q60 is a fantastic looking car straight out of the factory, but like a nice tailored suit, it can look even better with the addition of the right accessories. To bring out the car’s flowing lines, we opted to wrap the car with a red chrome wrap. The brilliant luster of the red chrome accentuates all of the angles and curves of the body of the car and truly ‘makes it pop’. The Q60 has a very organic, free flowing design, and the hyperreflective red chrome shows off these daring curves and deep creases exceptionally well. Like any car, we felt it could be a bit more aggressive and could do with some aero styling to really accentuate the curves the car comes with. The STILLEN design team then set to work shaping a Front Bumper Splitter featuring STILLEN Front Bumper Splitter for 2017 Infiniti Q60 – (with Winglet Extensions). With the front end spiced up to our satisfaction, we shifted our attention over to to the rear of the car, the STILLEN craftsmen then created a set of side splitters and rear spats to suit the aggressive feel we were going for. Both of these parts were custom fabricated exclusively for the STILLEN Q60.

Finishing off the ground effects package, STILLEN designed a Rear Diffuser for the Red Sport V36 Infiniti Q60 with a set of aggressive air channels and openings for a larger-than-stock dual exhaust. The STILLEN diffuser for Infiniti Q60 is no “one off” for a show car – this part is a production item you can purchase and install on your own Q60, along with the rest of the aero suite, including the STILLEN front splitter and winglets. While these days the majority of aftermarket manufacturing seems to be done overseas, but at STILLEN, we make all of our products right here in the USA. Every single STILLEN aero or appearance upgrade, intake and exhaust system is designed and manufactured in the USA, right here at STILLEN headquarters in Costa Mesa, California. Not everyone realizes that here at STILLEN we fabricate pretty much everything in-house, exterior parts, intakes, exhausts, suspension bits — our CNC machines, benders, welders and a team of experienced and talented craftsman makes it possible to do everything here. Now that we had the ground effects completed, the team still felt like our Q was still missing something. The rear end still lacked something, so next, the STILLEN artists then turned their attention to the rear spoiler. The initial idea was a simple, clean spoiler that would added a bit of height to the deck lid. After a few design studies, the team decided to step it up and came up with something that would compliment the dynamic lines of the Q60’s design, and created a custom hand crafted rear wing that completes the car and ties in beautifully with the overall design concept.

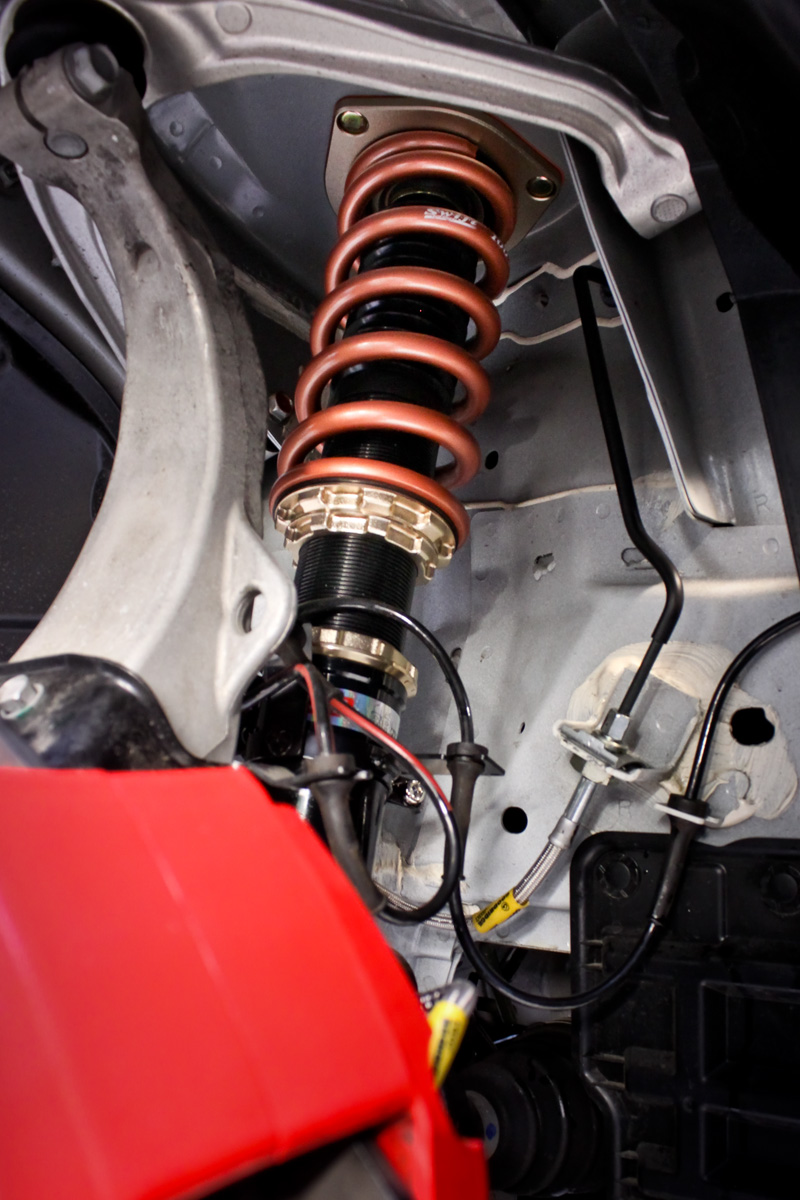

SUSPENSION

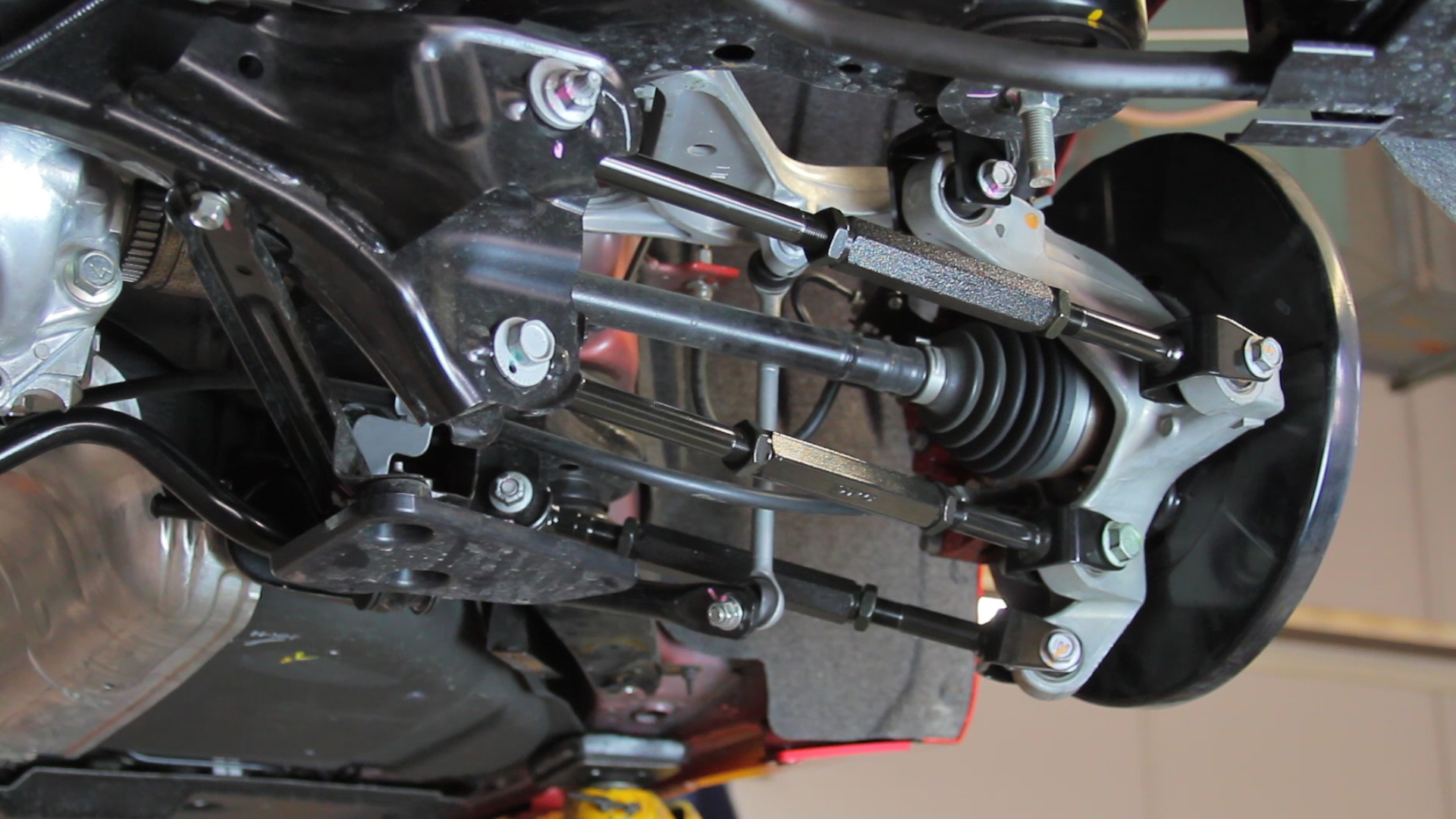

With the power and exterior styling completed it was time to focus on supporting all of that extra power and downforce. To do so, the STILLEN team partnered with RSR suspension, who used the STILLEN Q60 to develop and prototype a set of coil overs that are truly incredible. One difference that sets STILLEN builds apart from other SEMA showcars is that our cars are built to be driven. Our Q60 Redsport is no trailer queen – this car was driven to the show and then driven home. Since this car would be seeing hundreds of miles of actual road use between STILLEN HQ in Costa Mesa and Las Vegas, it was vital that the car not only look good, but could also retain its handling performance. The team at RSR hit another home run with the RSR Coilovers for 2017+ Infiniti Q60 we had fitted to the car – we really enjoyed these dynamic coil overs. The ride quality is fantastic when cruising on the freeways and the car carves through the canyons with ease.

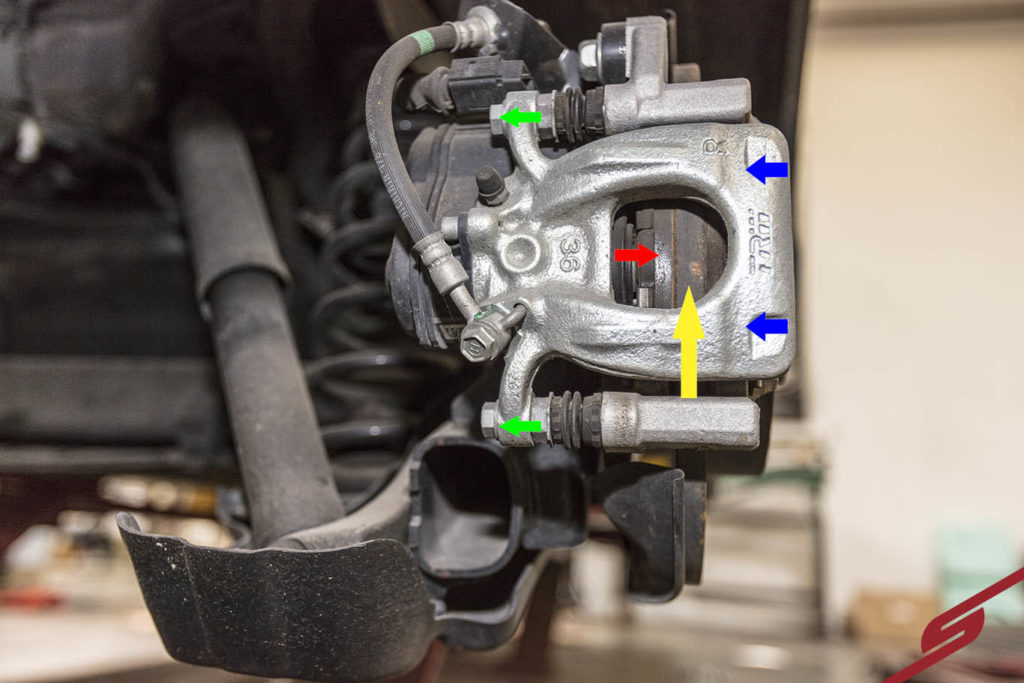

To make sure that the alignment was correct after the coil over installation and subsequent ride height lowering, SPC suspension provided a complete set of adjustable suspension including front upper control arms and SPC Suspension Rear Camber, Toe and Setback links for 2017 Infiniti Q60. By installing the adjustable SPC suspension the STILLEN technicians were able to precisely dial in the alignment ensuring excellent handling characteristics

No car would be complete without the right wheel and tire package. Wheels are one of those items that can make or break a car. For years STILLEN has chosen VOSSEN Wheels for 2015+ Infiniti Q50 / Q60 and NITTO tires for their vehicles. On this car though they wanted something a little different. To accomplish this the STILLEN team selected the Vossen X Work line of wheels. Particularly, the VWS-1. Work wheels is a leading Japanese manufacturer of high end wheels and the collaboration between Vossen and Work has resulted in a melding of Japanese technology with American style. These two piece wheels feature a high luster polished lip with a matte gunmetal center and polished anodized barrel.

NITTO tires have been the preferred tire for STILLEN for many years. Offering a wide range of tire selections for everything from race cars to passenger cars and even offroad vehicles. For the STILLEN Q60 project STILLEN selected the INVO series of tires. INVO tires are designed specifically for the luxury sports car enthusiast. They offer excellent performance and grip without sacrificing comfort.

We’re thrilled with the end result of how our 2017 SEMA project came out – the team here at STILLEN feels that the Q60 we put together strikes the perfect balance between high end street luxury, with design inspired by our race-winning heritage tempered with elegant style.

STILLEN Vice President Kyle Millen had this to say of the project:

“The STILLEN Infiniti Q60 project car is one of my favorite cars out of the many projects we have created. The team at STILLEN did an amazing job and made a car that is truly one of a kind. From the work of the body craftsmen, the engineers and fabricators working tirelessly on the performance parts, I am extremely proud of the effort put into this car and the end result.”

If you have any questions about the Infiniti Q60 3.0t or any STILLEN products for the Infiniti Q60 on our website, give us a call at (866) 250-5542, email sales@stillen.com, or message us on our Live Chat!

This kit is expected to begin shipping by Mid-September (update 9/16 – Now Shipping!).

This kit is expected to begin shipping by Mid-September (update 9/16 – Now Shipping!).