Recently, the team at Stillen had the incredible opportunity to visit the SEMA Garage in Diamond Bar, California, for an exclusive early access hands-on experience with two highly anticipated vehicles: the 2024 Lexus GX550 and the 2024 Toyota Land Cruiser. This behind-the-scenes look at these vehicles before their official release was an invaluable opportunity for us to kickstart our research and development process, allowing us to gain insights and explore the potential for customization. In this blog post, we’ll share our experience at the SEMA Garage, our initial impressions of the vehicles, and our excitement for the future of off-roading with these remarkable platforms.

Exploring the SEMA Garage:

Located in the heart of Diamond Bar, California, the SEMA Garage serves as a premier automotive innovation hub, providing industry professionals with access to cutting-edge tools, resources, and early vehicle prototypes. As pioneers in the aftermarket automotive industry, Stillen was thrilled to be invited to the SEMA Garage for a hands-on experience with the 2024 Lexus GX550 and Toyota Land Cruiser.

Upon arriving at the SEMA Garage, we were greeted by the sleek silhouettes of the 2024 Lexus GX550 and Toyota Land Cruiser, both eagerly awaiting our inspection. With anticipation building, our team wasted no time delving into the vehicles, eager to uncover the engineering marvels that lay beneath the surface.

Initial Impressions:

As we began our exploration of the 2024 Lexus GX550 and Toyota Land Cruiser, it quickly became apparent that these vehicles were designed with off-road enthusiasts in mind. From their rugged exteriors to their robust underpinnings, both the GX550 and Land Cruiser exuded a sense of adventure and capability.

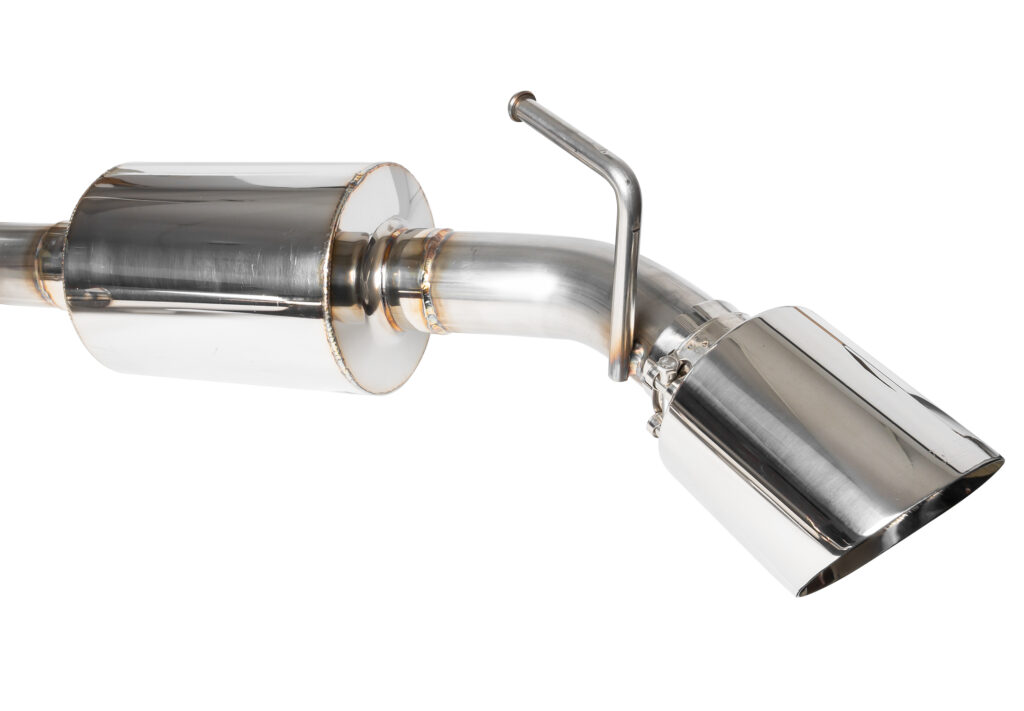

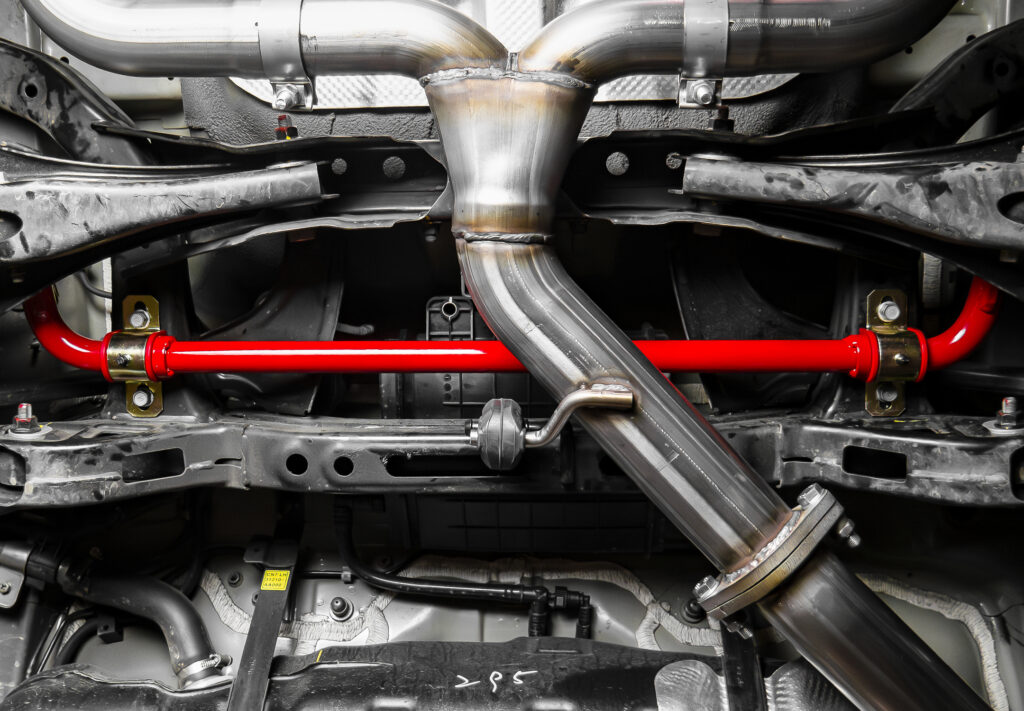

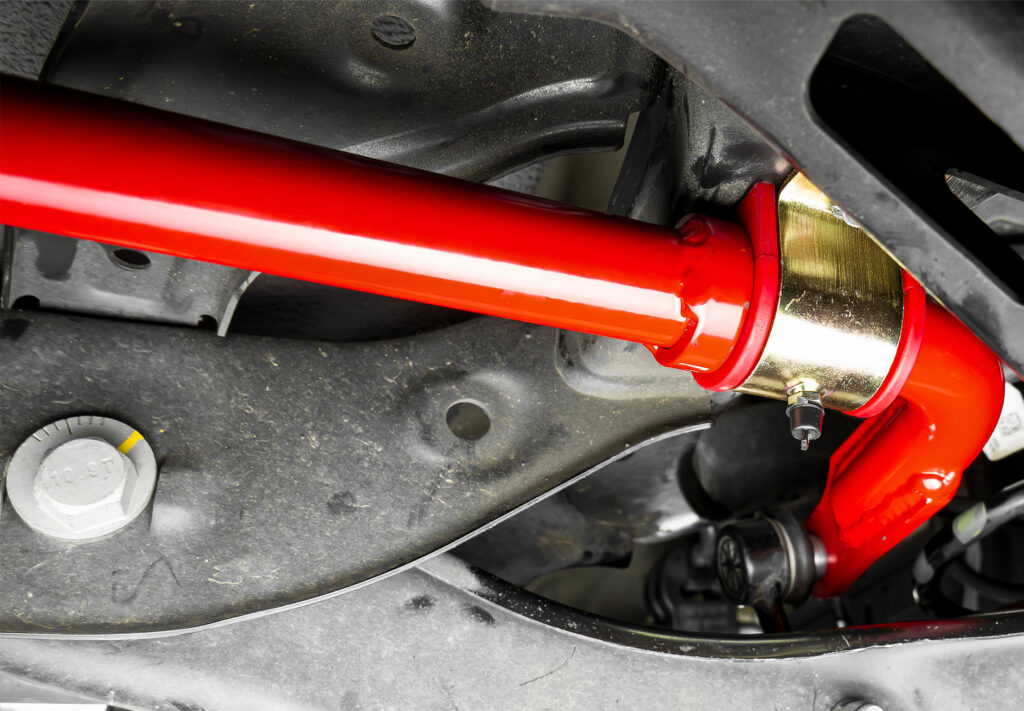

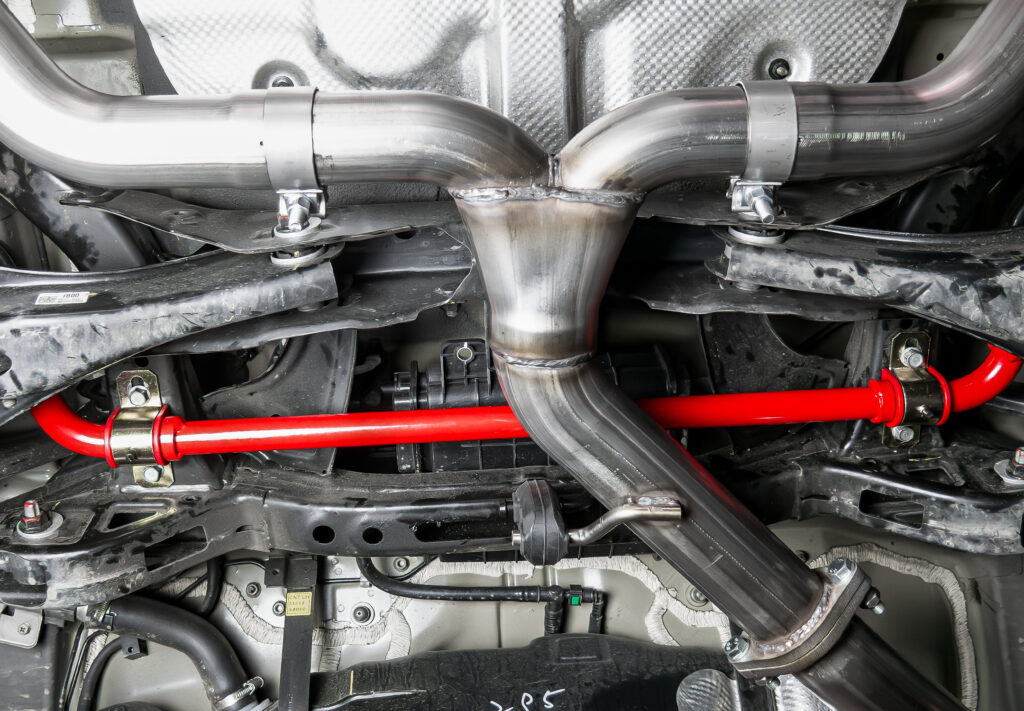

One of the standout features of the GX550 and Land Cruiser was their exceptional build quality and attention to detail. Every component, from the suspension system to the drivetrain, was meticulously engineered to withstand the rigors of off-road terrain while delivering a smooth and comfortable ride on the pavement.

Hands-On Experience:

During our time at the SEMA Garage, we had the opportunity to get up close and personal with the 2024 Lexus GX550 and Toyota Land Cruiser, exploring their interiors, examining their mechanical components, and gaining a deeper understanding of their design philosophy.

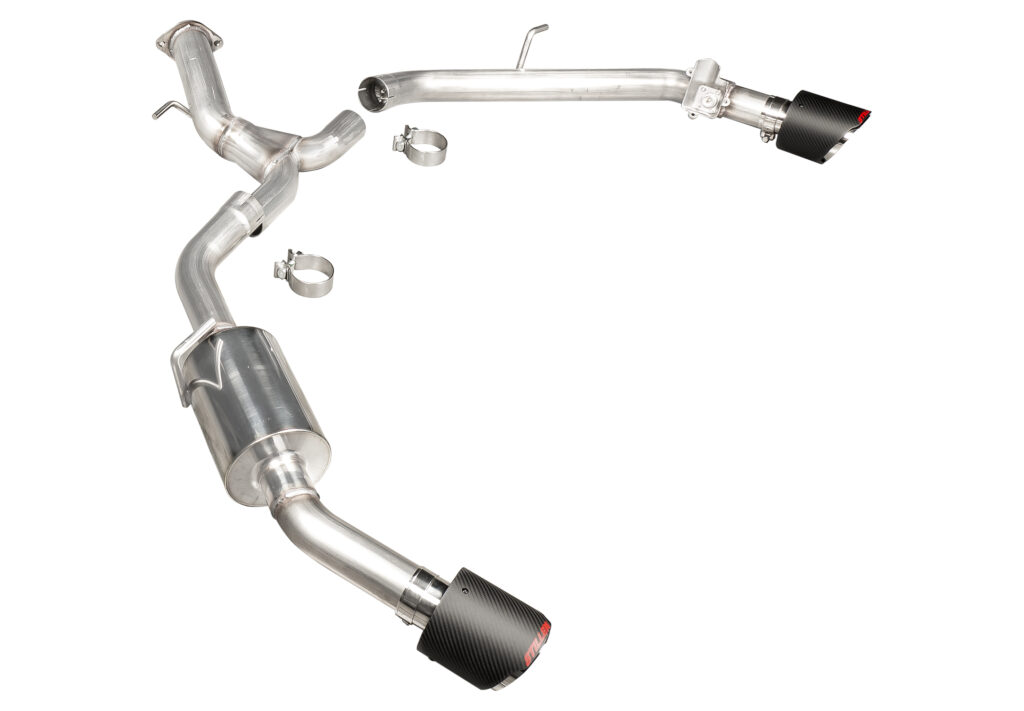

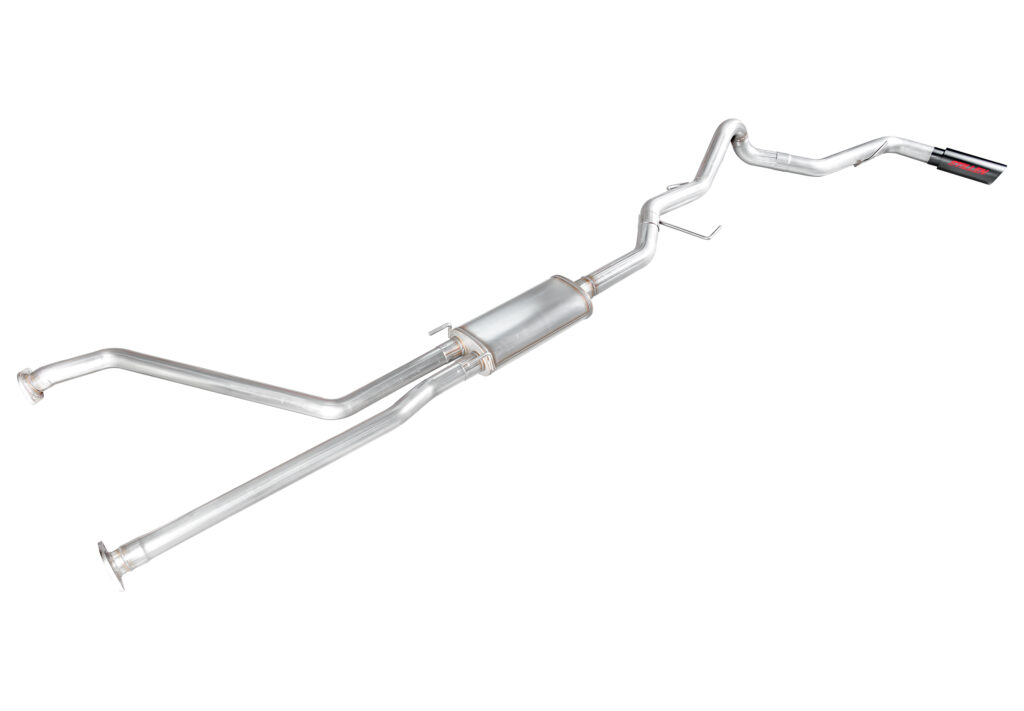

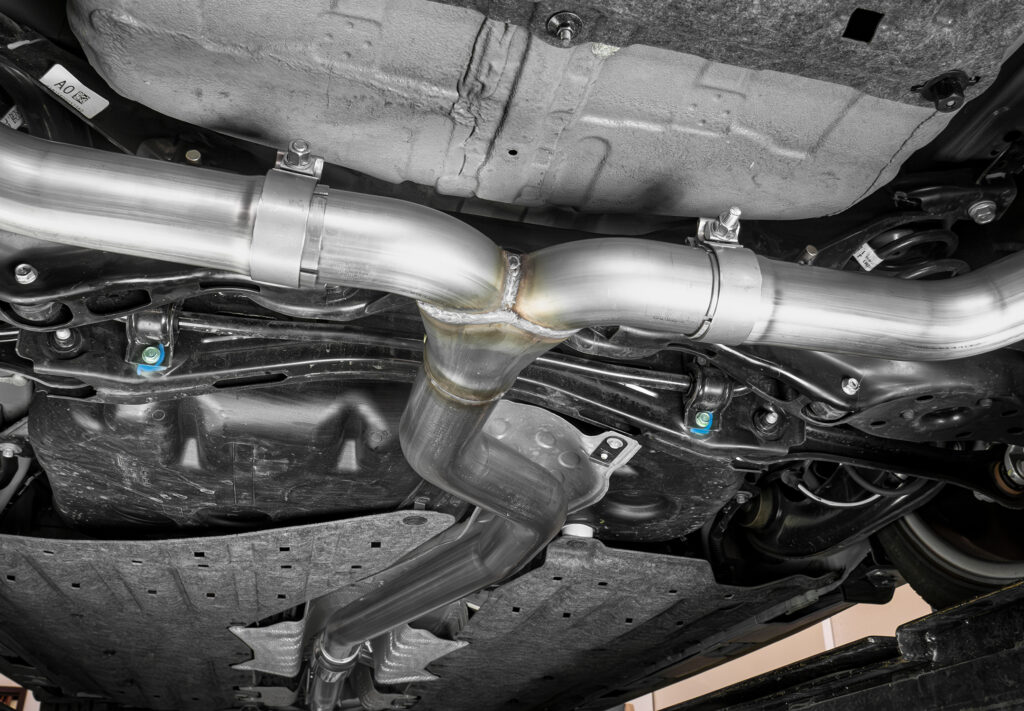

One aspect that particularly impressed us was the level of customization potential offered by both vehicles. With their modular construction and versatile platforms, the GX550 and Land Cruiser are primed for aftermarket upgrades and enhancements, allowing off-road enthusiasts to tailor their vehicles to suit their specific needs and preferences.

Looking Ahead:

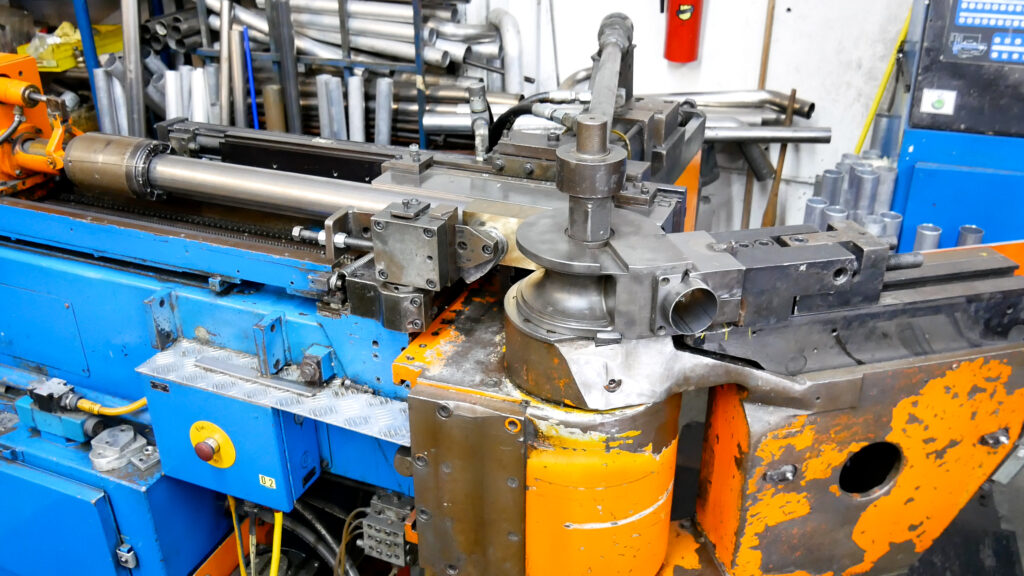

As we bid farewell to the SEMA Garage and the 2024 Lexus GX550 and Toyota Land Cruiser, we left with a renewed sense of excitement and anticipation for the future of off-roading. The hands-on experience provided invaluable insights that will inform our research and development efforts as we strive to create innovative aftermarket solutions for these exceptional vehicles.

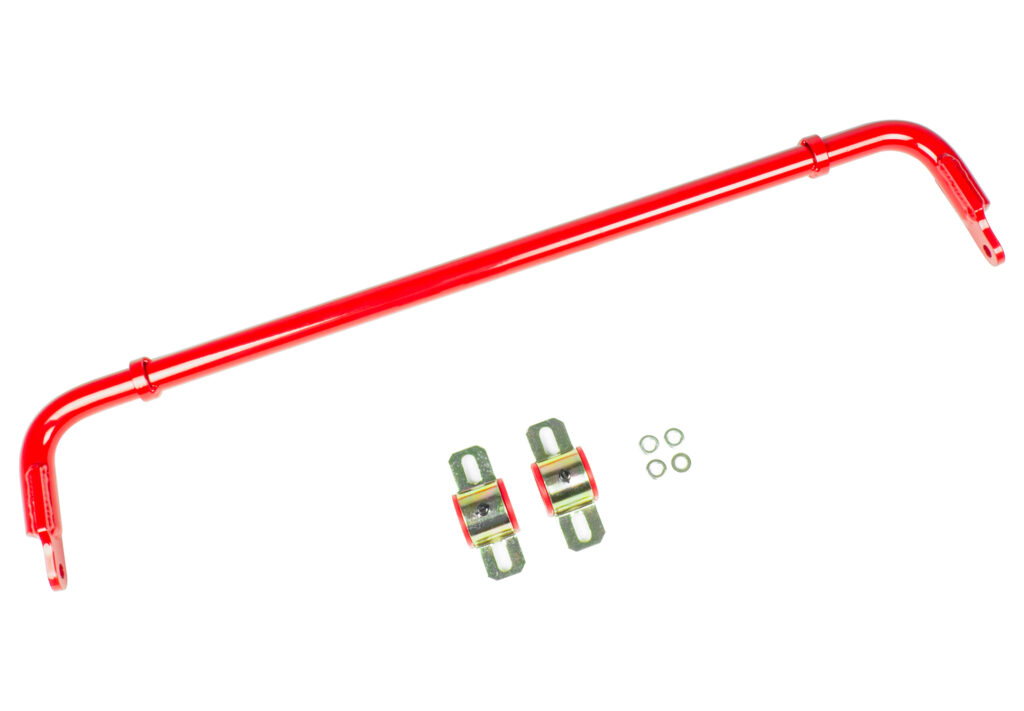

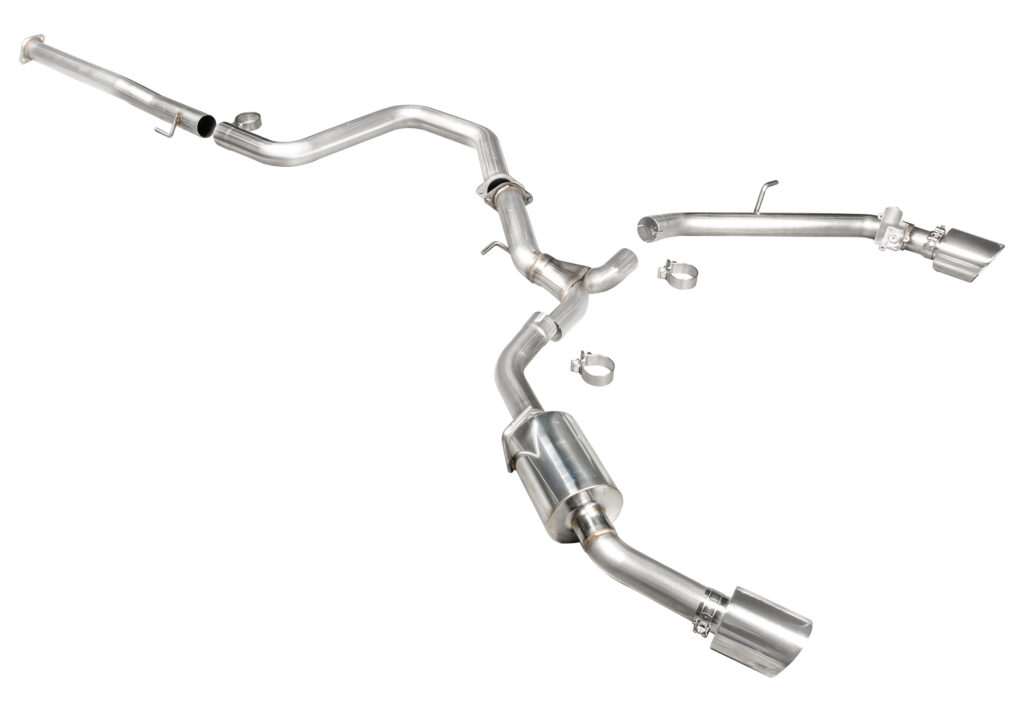

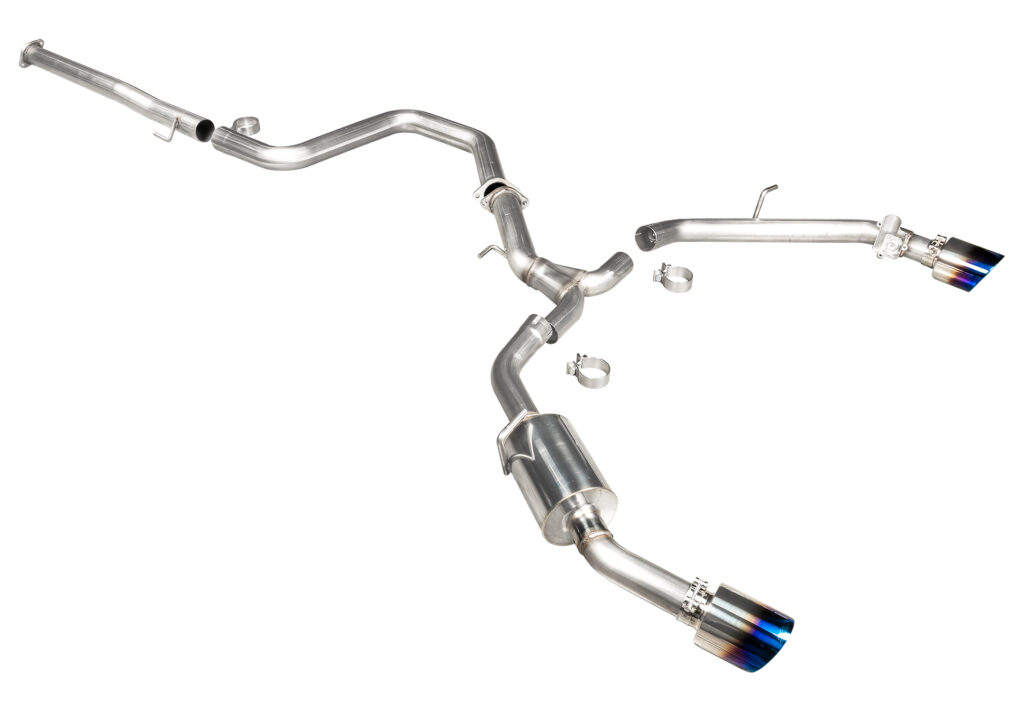

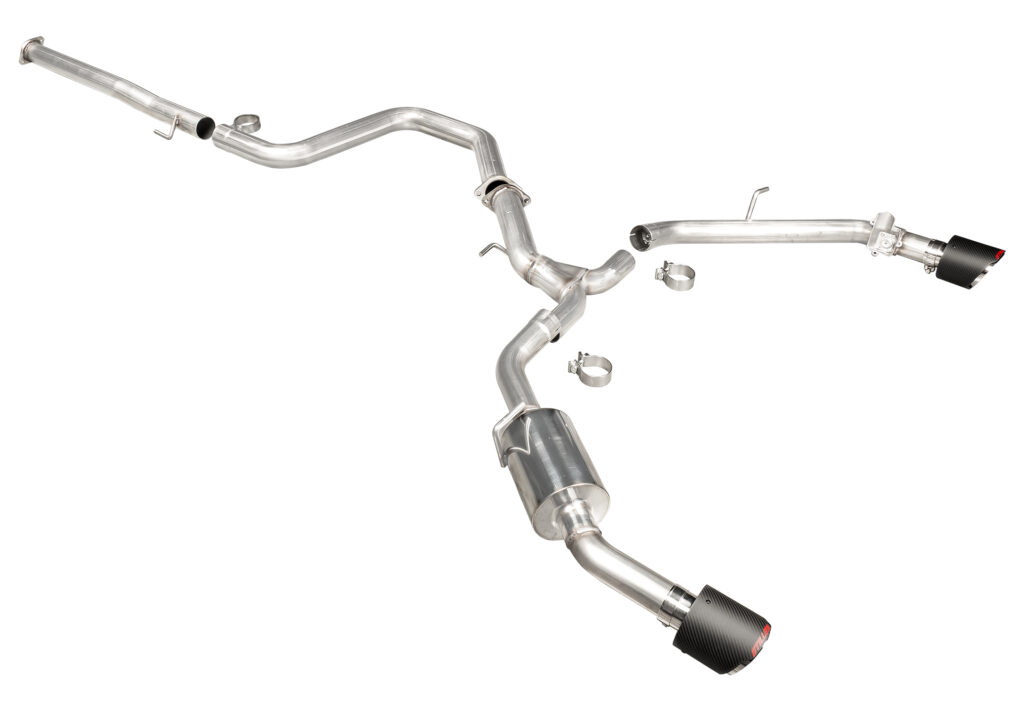

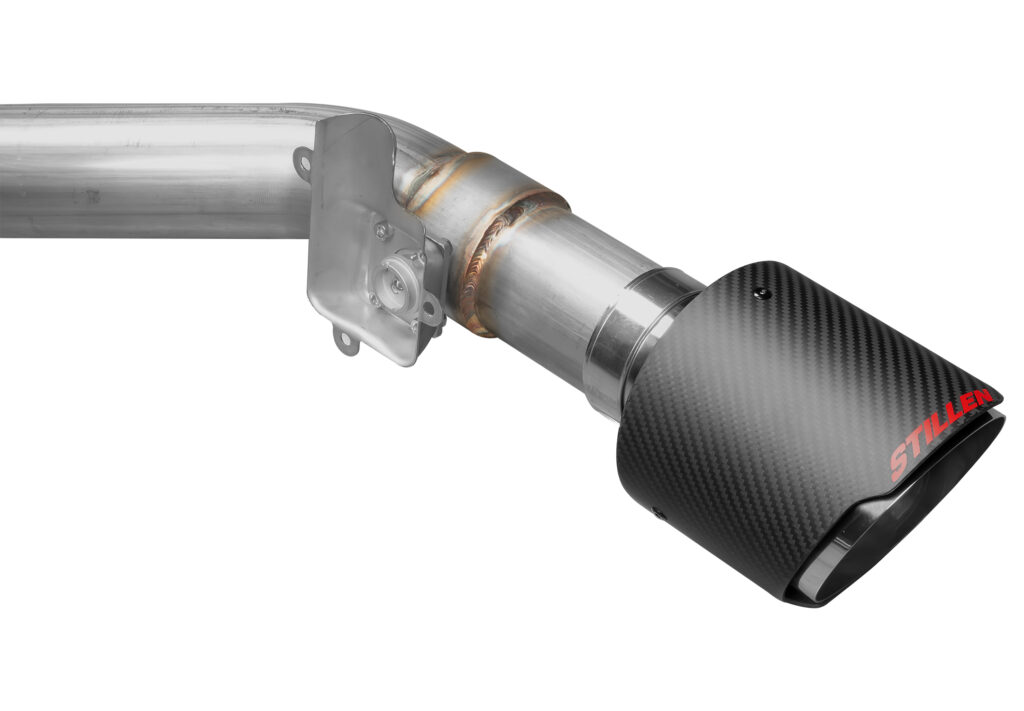

In the coming months, you can expect to see the fruits of our labor as we unveil a range of performance upgrades and accessories designed specifically for the 2024 Lexus GX550 and Toyota Land Cruiser. Whether you’re seeking enhanced off-road capability, improved performance, or customized styling, Stillen has you covered.

Conclusion:

Our visit to the SEMA Garage was a truly unforgettable experience that reaffirmed our commitment to pushing the boundaries of automotive innovation. With the 2024 Lexus GX550 and Toyota Land Cruiser leading the way, we’re excited to embark on this journey of exploration and discovery, bringing you the very best in aftermarket automotive solutions. Stay tuned for updates, and we’ll see you on the trails!