Best Brake Upgrades 101: Rotors & Pads

By Richard Fong

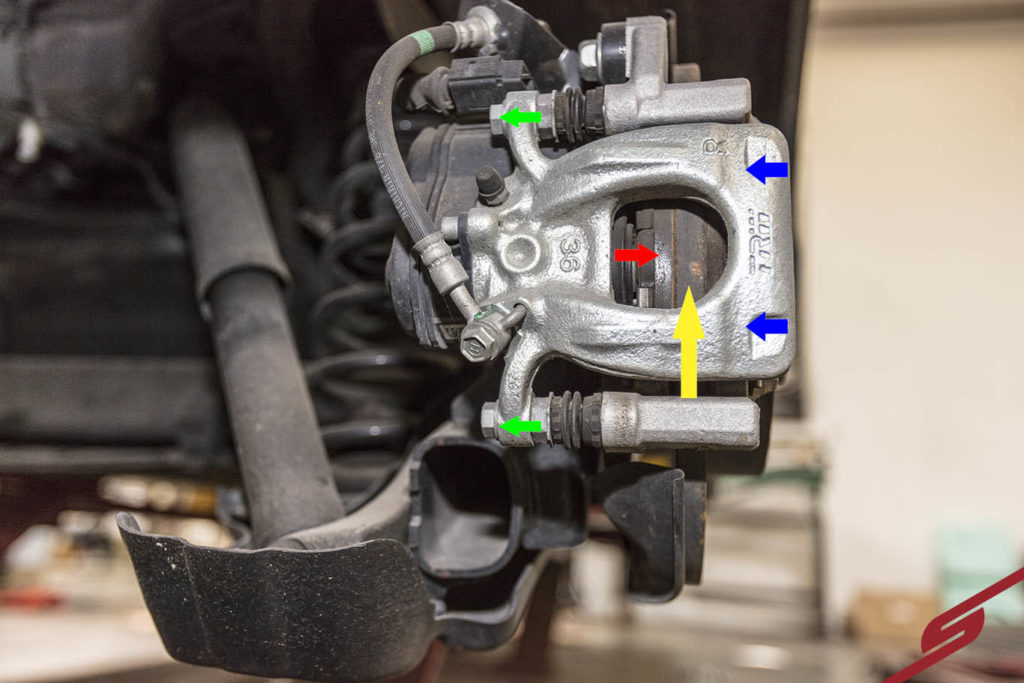

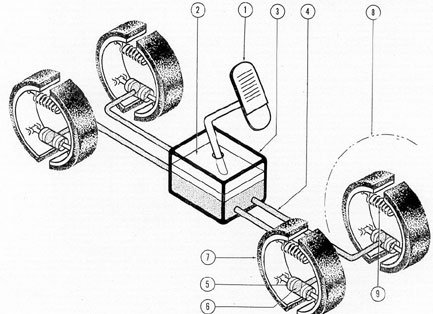

There’s no point in being able to go if you can’t stop. While an engine provides locomotion to a car, the braking system is what brings your vehicle to a stop. The average automotive brake system is hydraulic and typically consists of the pedal assembly, vacuum booster, master cylinder, hydraulic lines, calipers, rotors and pads – and of course, on nearly all modern vehicles, an Anti-Lock Brake System module and pressure tank.

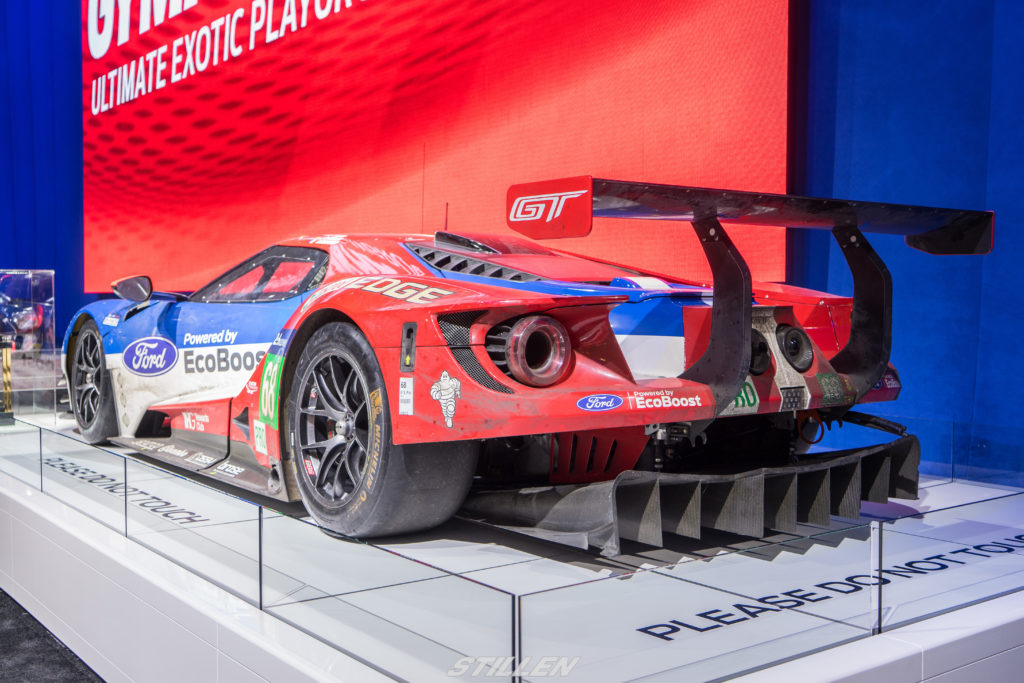

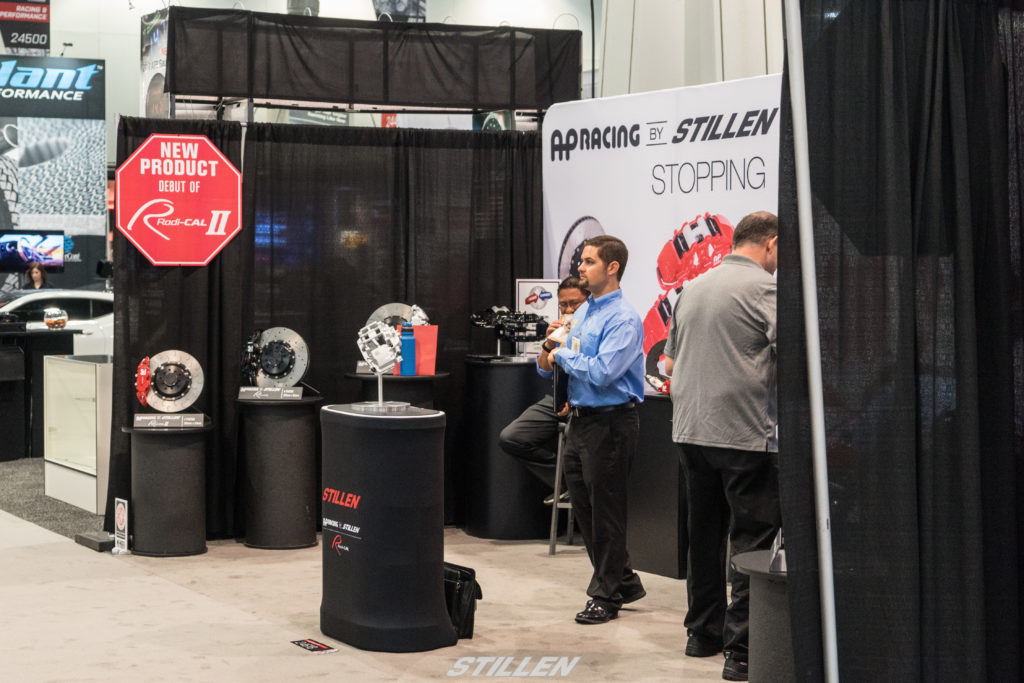

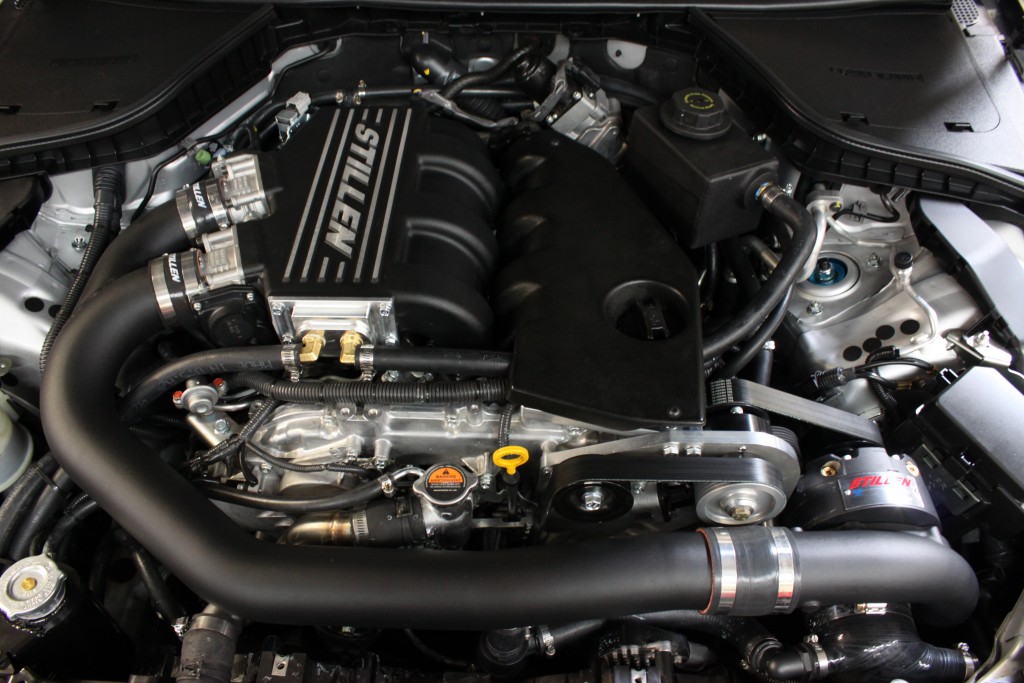

The braking system is not only a CRITICAL performance element, it’s also imperative for safety and the safe operation of a vehicle. That’s why STILLEN offers Brake Upgrades for a variety of vehicles, from big brake kits to performance replacement parts.

As is often the case, many standard vehicle components are designed as a compromise – balancing quality versus price, versus Noise Vibration Harshness (NVH) concerns – the end result being a pad that isn’t well suited for trackday performance. This means that in all likelihood, your OEM brake pads probably don’t do very well in ‘high performance’ conditions.

Brake Pad Construction

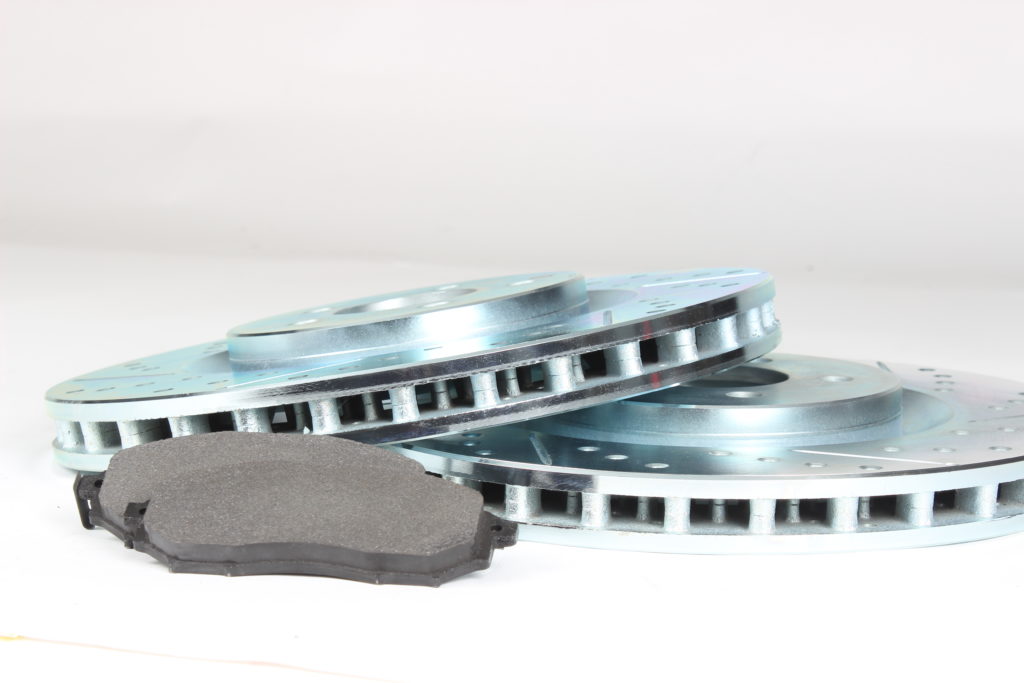

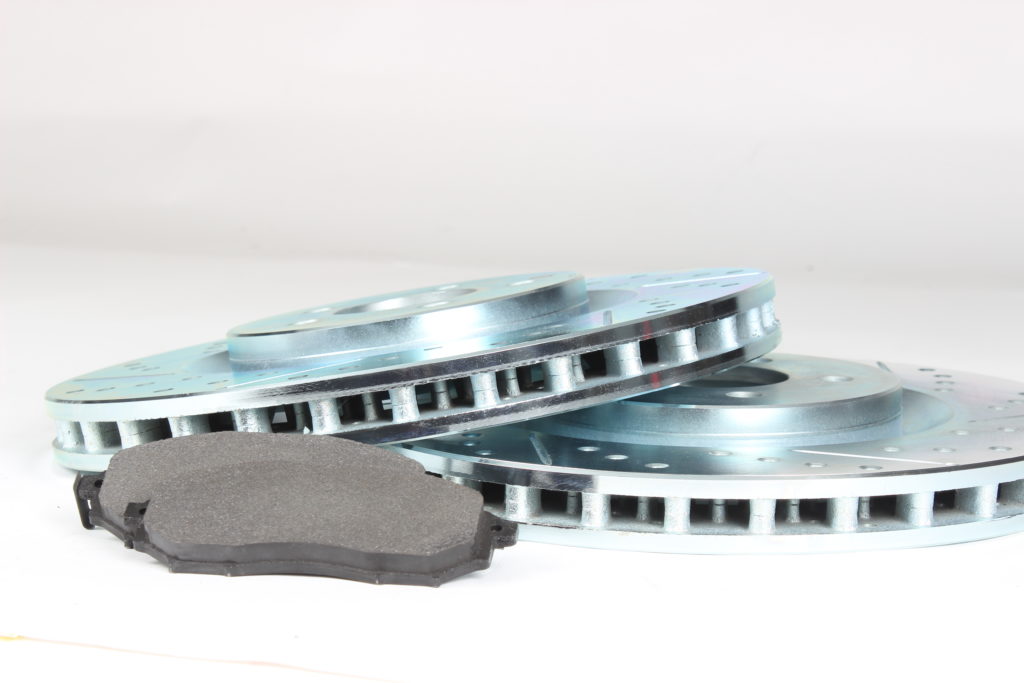

Brake pads are composed of a backing plate and a friction compound that creates friction when placed in contact with the brake rotors, enabling a vehicle to stop. The way your brakes work is kind of like how the brakes of a bicycle work. Pushing the pedal causes the calipers to squeeze the pads against the spinning wheel hub/rotor, slowing its rotation, much like your bike’s rubber brake pads grab the edge of the wheel of your bicycle to bring you to a stop.

Before moving on, we need to remind you that a high performance pad is going to be noisier and dustier – those are the facts. If you’re wanting a pad that offers extreme performance without dust or noise, know that it just doesn’t exist, at any price. Sorry, but if you want performance from your brake system, you’re going to have to deal with brake dust.

Your Stock Brakes Probably Aren’t As Good As You Think

With the exception of premium performance-oriented vehicles that include performance brake components from the factory, most vehicles are equipped with braking systems that are best described as “Adequate”. If you take the average stock vehicle to the track or even on a spirited drive, and you’ll quickly learn its shortcomings. The sad thing is, many car’s brake systems can start to get overwhelmed after just a few aggressive corners.

What happens if my brakes can’t deal with the demands of performance driving?

To understand the importance of a good brake compound and just how big a role it plays, let’s do a quick thought exercise.

Imagine accelerating down a stretch of canyon road, you’re accelerating hard on the straights, and then braking just before engaging a turn, or series of switchback curves. The first time you hit the brake pedal, everything works as it should, shaving speed and allowing you to hit the apex of the turn with ease. However, a few corners (or hotlaps) later, suddenly, the pedal gets all mushy, and instead of slowing and allowing you to adjust your line, the car just plows ahead, because the brakes don’t have any bite. You desperately stomp on the brakes in hopes you can still adjust your speed, correct and make the turn– but your efforts are in vain. Before you realize it, you’re way past the apex and are either off line or off track, or even worse, into the guardrail or Armco barriers. This is the biggest problem of an insufficient brake system rearing its ugly head. This is the beast known as Brake Fade.

What is Brake Fade, exactly?

Brake fade is the enemy of safe and reliable braking and it’s not your friend. Brake fade occurs when the friction efficiency and/or heat capacity of the brake pads or rotors is exceeded, and as a result, the ability of the brake system to slow or stop the vehicle becomes compromised. Whether it’s on a twisty mountain pass or on a racetrack, when you discover the limits of your vehicle’s braking performance firsthand, it leaves much to be desired in terms of performance. Fortunately, the aftermarket could be the answer to your problems, because chances are, someone offers a solution for your application. There are a few ways to mitigate brake fade.

Bring Back the Friction

One of the best performance mods for your car and most straight-forward upgrades you can make is a set of Brake Pads. Brake pads, like rotors and fluid, are wear items that can be replaced with upgraded versions of replacement parts. Most factory brake pads are designed to be as quiet as possible with as little dust as possible. These characteristics require compromises that take away from the performance of your brake pads.

Can You Put Race Pads On And Drive On The Street?

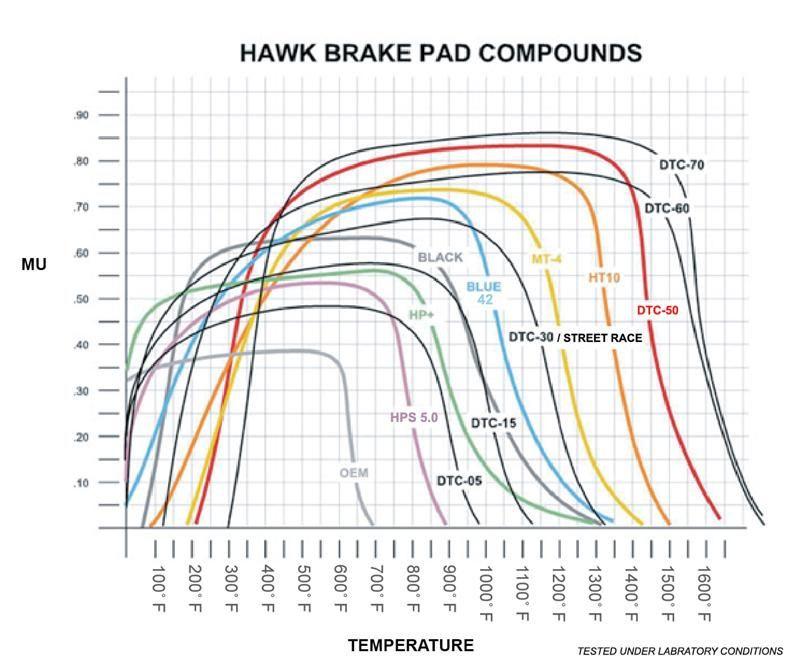

The demands of racing versus stop and go traffic are very different, OEM street pads don’t perform their best under race conditions, and outright RACE brake pads won’t perform well if used for street driving conditions. Logically, one might think, pads designed for “RACE” performance must be overkill for the needs of street driving, right? Frankly, no.

Way back in the good ol’ days of 2002, Popular Mechanics compared Jeff Gordon’s #24 NASCAR Monte Carlo against a fresh-off-the-line FWD Monte Carlo SS to get an idea how the race car performed relative to its streetcar namesake. One would think that the race car’s massive brakes would make it the obvious winner, right? Both cars were tested as is standard practice for a head-to-head – cold, like your car is when you first start driving after being parked for a while. Can you guess what happened?

(ref: Popular Mechanics, November 2002, A Tale of Two Chevys)

Well, the street car Monte Carlo outperformed the #24 NASCAR racecar’s gargantuan race brakes and the street car stopped much shorter – the polar opposite of what ‘common sense’ would suggest. That generation of Monte Carlo wasn’t exactly a performer either, making its victory over the racecar that much more shocking.

Why? Because of the temperature the brakes were designed to work at. The NASCAR race car’s brakes are designed to be used HARD, over and over again when hot, braking from speeds well over 100… to get that kind of performance when the brakes are that hot, the engineers had to sacrifice performance when cold.

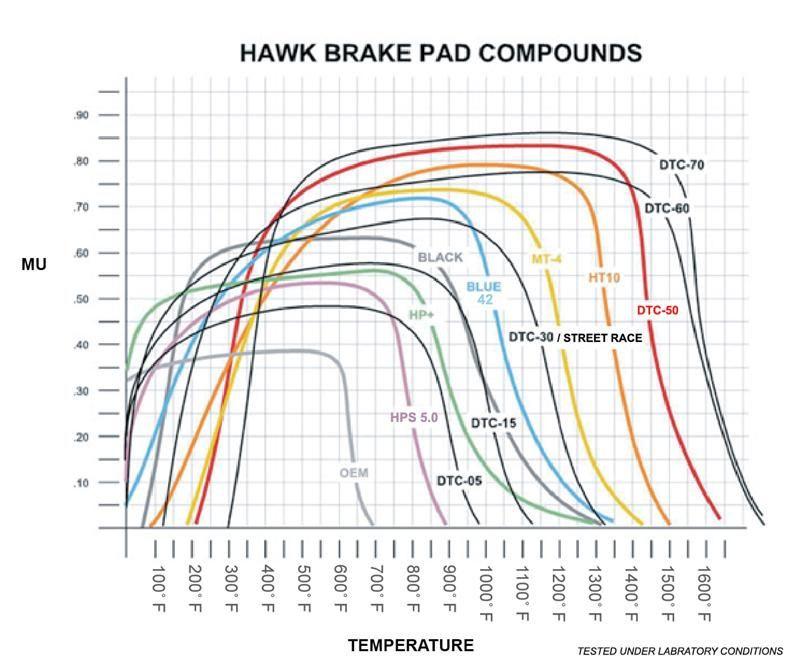

This chart from HAWK Performance offers a great visual for the temperature ranges that brake pads are designed to operate in. As you can see, pads that perform well cold do not perform well past 700*f or so, and conversely, pads that perform well when hot don’t start to grab until 200-300* f.

The Right Pad for the Right Purpose

Each pad type and compound is optimized depending on your vehicle’s intended purpose. There are a plethora of High Performance OE Replacement Brake pads available from STILLEN, DBA Brakes and Hawk Performance to name a few, and these pads are offered in a variety of friction compounds ranging from organic and ceramic to semi-metallic to suit a variety of different driving demands.

The other thing to note here is that sometimes, a car is factory-equipped with high performance brake pads, but the generic replacement available from the local auto parts store might perform terribly by contrast. So, despite every part of the system working properly, underperforming brake pads mean it suddenly takes much more distance to stop than it used to- and if you’re used to the car’s original stopping distance, this increased in stopping distance could cause an accident, so be sure that the replacement pads you’re installing are able to handle the way you plan to use them, before you buy.

Pro-Tip: If the brake pad has “Quiet” in the name, it’s a safe bet that pad won’t do well on a track.

Let’s take a look at some of the pros and cons of different brake pad compounds so you can better determine what might be best for your needs.

Picking The Right Brake Pad Compound for the Way YOU Drive

Organic (Common OEM Material)

Pros: Less aggressive rotor wear, decent initial bite, manageable brake dust generation

Cons: Mediocre braking performance, tends to wear quickly, prone to brake fade

Organic pads offer good initial bite (initiation of friction and slowing of the vehicle) and modulation for daily driven vehicles, but generally suffer rapid wear and fade when subjected to aggressive driving.

Ceramic (Common OEM Material, Aftermarket Upgrade)

Pros: Moderate rotor wear, good wear characteristics, less prone to brake fade, moderate dust production, ideal for rotors lacking slots or cross drilling, the middle ground between organic and semi-metallic pads

Cons: Higher cost, limited compound options, less aggressive friction traits, not ideal for the track

Ceramic pads cost more but take the best traits of organic pads and can add longevity as well as reduced brake dust production. However, these pads suffer accelerated wear under heavy loads and are not ideal for track or heavy-duty braking situations.

Semi-metallic (Common Aftermarket Material, Aftermarket Upgrade)

Pros: Broad selection of available compounds, improved resistance to fade, improved heat rejection when used on slotted or cross-drilled rotors, permits tailoring of braking performance traits depending on driving conditions by changing compounds

Cons: Potentially aggressive rotor wear, excessive dust, noise (brake squeal)

Semi-metallic pads tend to resist fade better and offer superior heat capacity and dissipation compared to organic or ceramic pads. They are offered in a variety of compositions enabling the end user to choose the braking characteristics desired of their vehicle. When choosing a semi-metallic pad, aggressive initial bite could be desirable in the case of a vehicle driven hard for short intervals.

The counterpoint is that this pad could eventually suffer from fade with prolonged aggressive driving. By comparison, a semi-metallic pad formulated for endurance offers increased heat capacity for longer driving intervals, but will likely lack initial bite when cold and suffer reduced braking performance until brought up to optimal operating temperatures. This is not ideal for short driving intervals or street driving since the ideal temperatures are much higher and might not be reached under these conditions.

In other words, semi metallic endurance RACING brake pads will be unable to perform for “street use” because they will not be at their intended operating temperature a vast majority of the time – meaning it’s not smart to drive from your house to the race track on your ‘trackday’ brake pads. It won’t be fun when you roll right past that first stop sign or can’t slow down as you get off the freeway because the RACE COMPOUND brake pads are too cold.

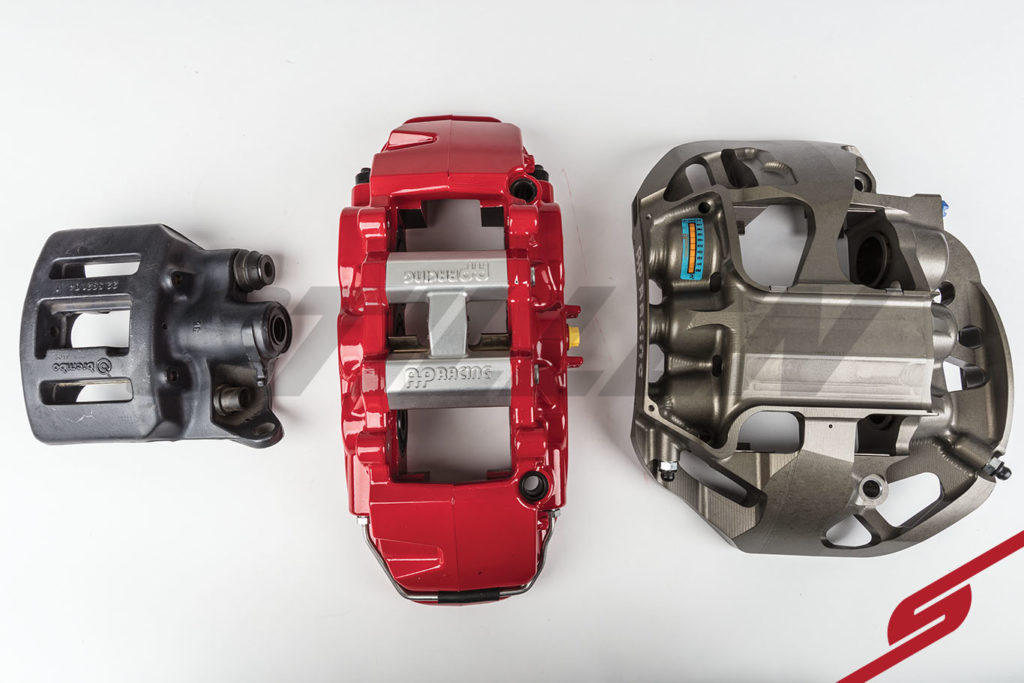

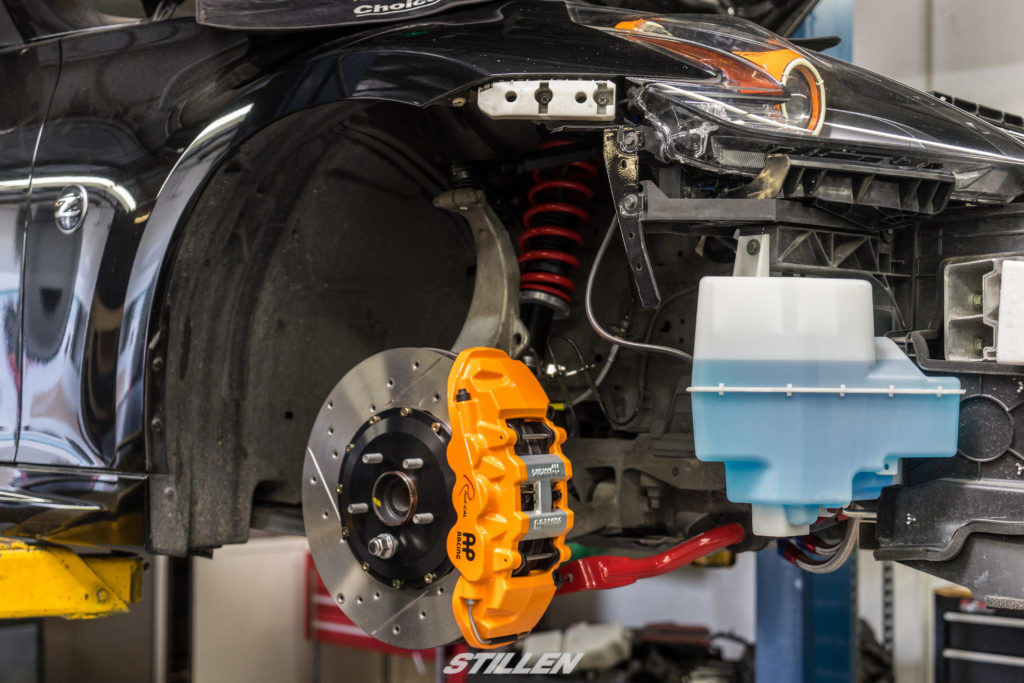

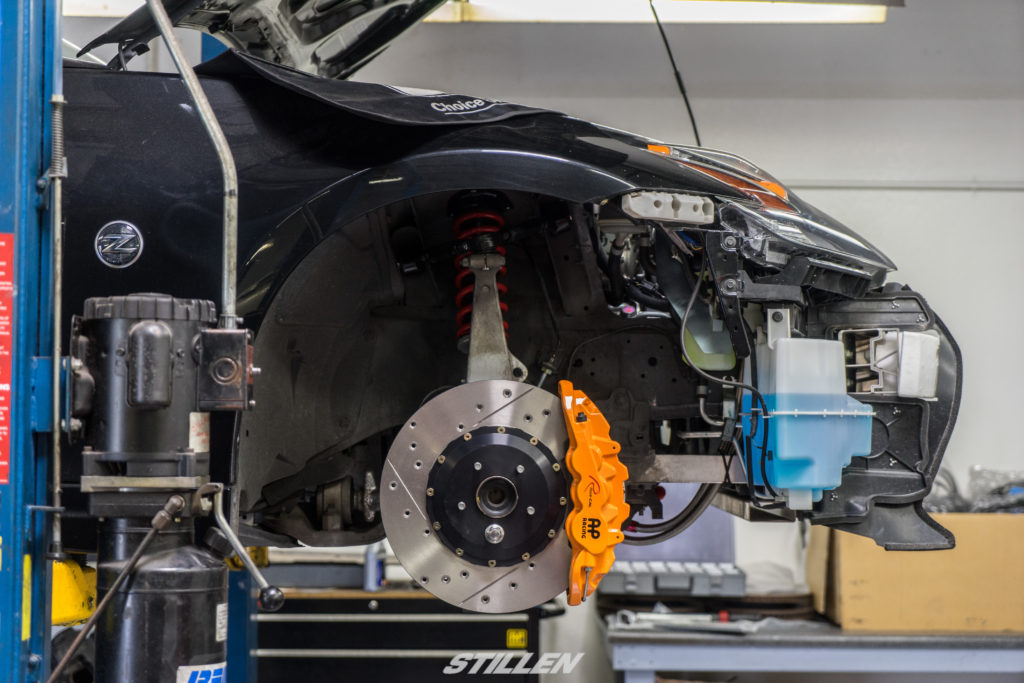

As the only USA Distributor of AP Racing products, we’ve got a huge selection of replacement and performance replacement brake pads for a variety of applications here at STILLEN in stock and or readily available to suit your needs from the most trusted manufacturers in performance brakes. Whether it’s a daily driver or a track rat, we likely have a solution available – talk to our team today to see what we have for your application.

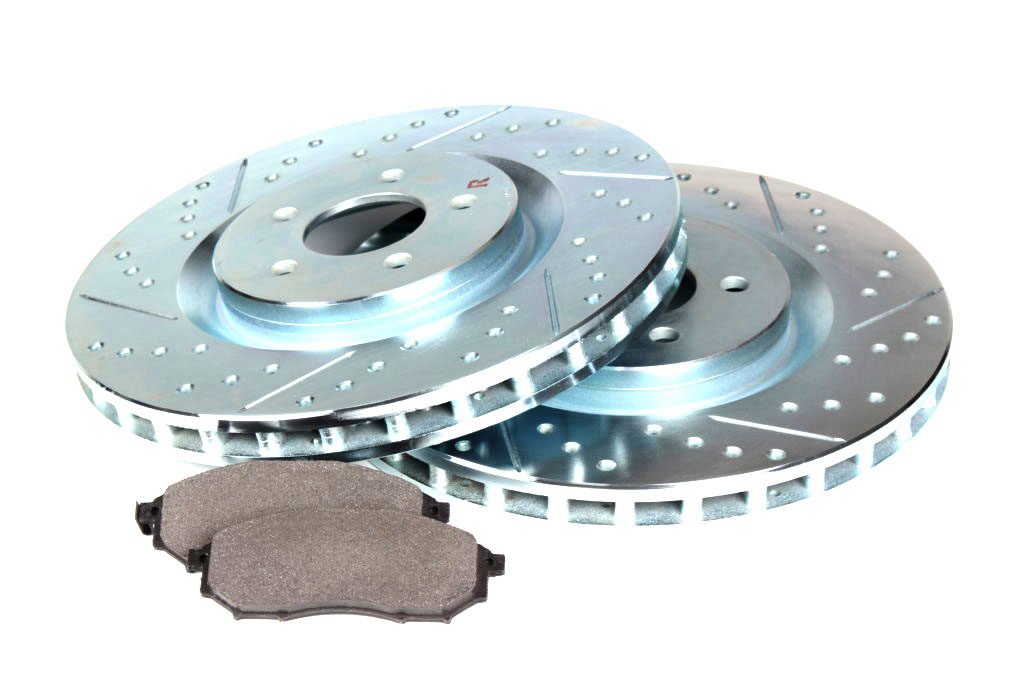

Release the Heat

Another common brake system improvement involves upgrading the surface that the brake pads apply friction to, the Brake Rotors. Brake rotors are not only a friction surface, they also serve another important function – they are also heat sinks. This means that they must draw away and dissipate the heat produced by the friction of the pads efficiently to stave off brake fade and ensure consistent braking performance. Factory brake rotors are typically made of iron, because it’s inexpensive and offers longevity and enough heat capacity for the average everyday driver. Trick is, the way the “average driver” drives a car is nothing like the ‘Spirited Drives’ you and I enjoy.

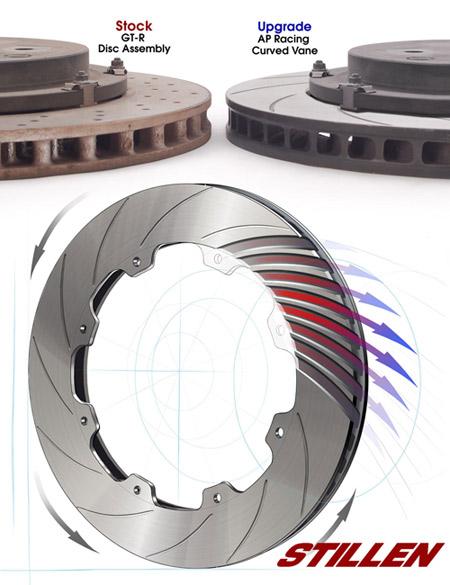

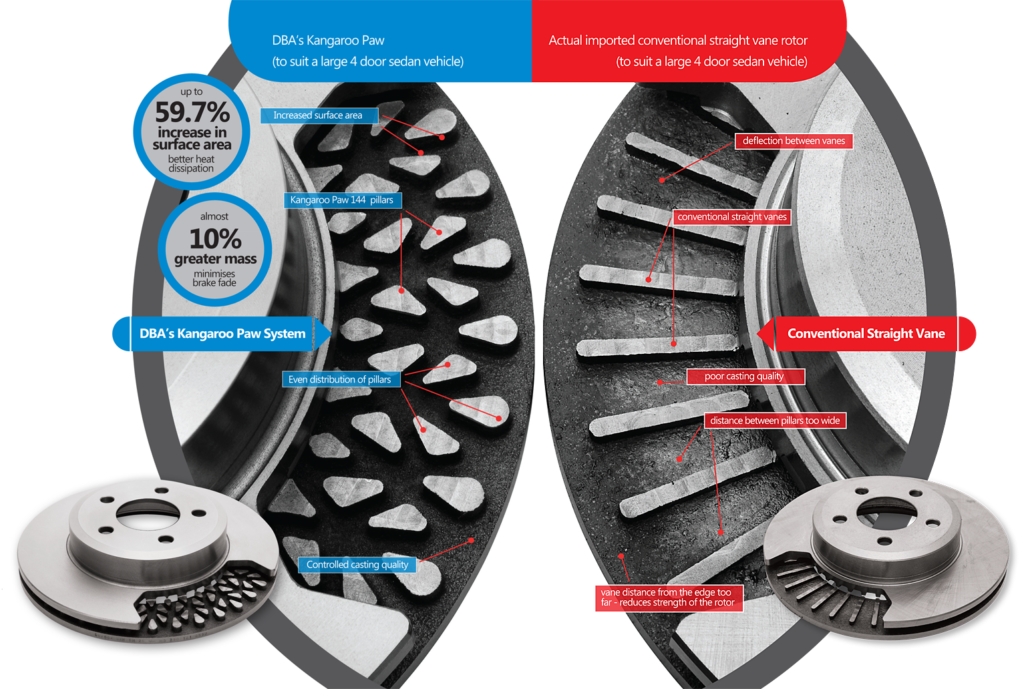

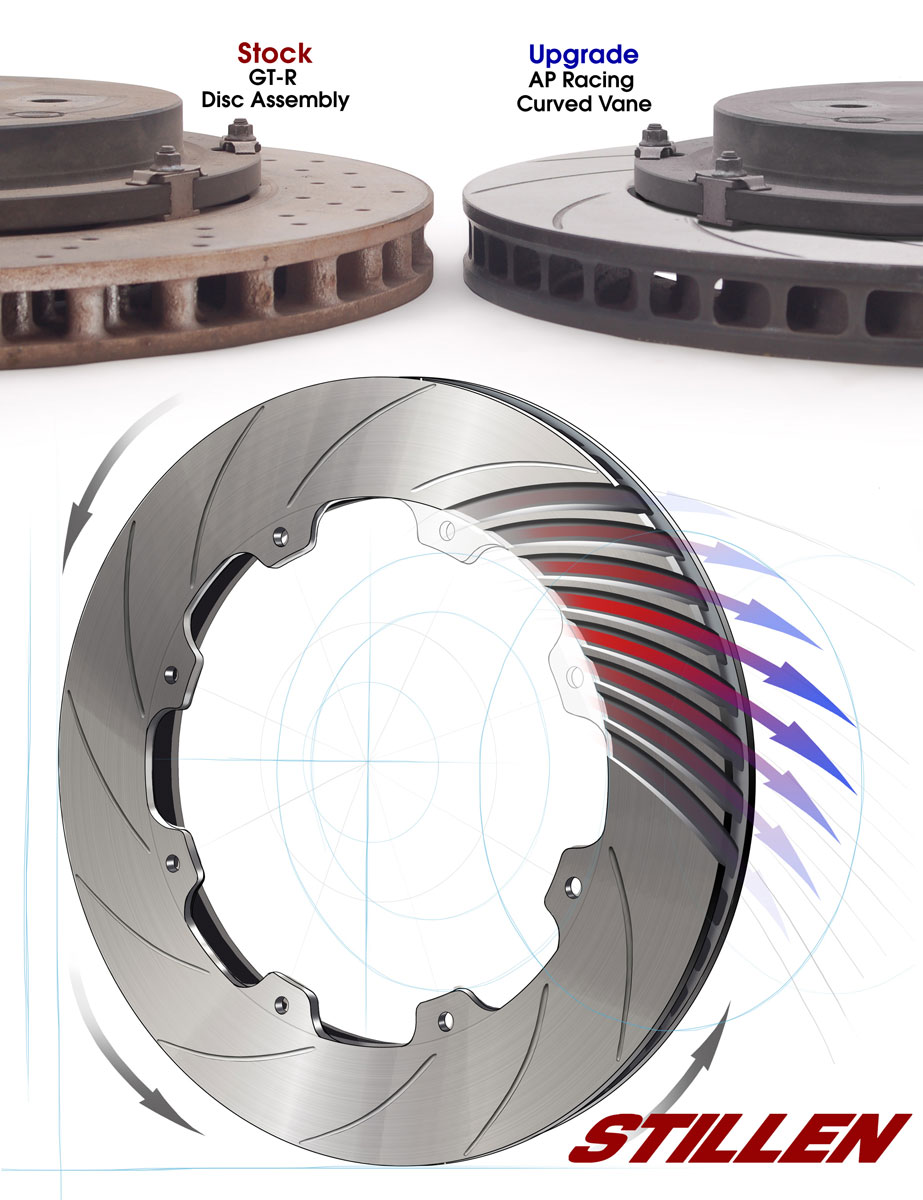

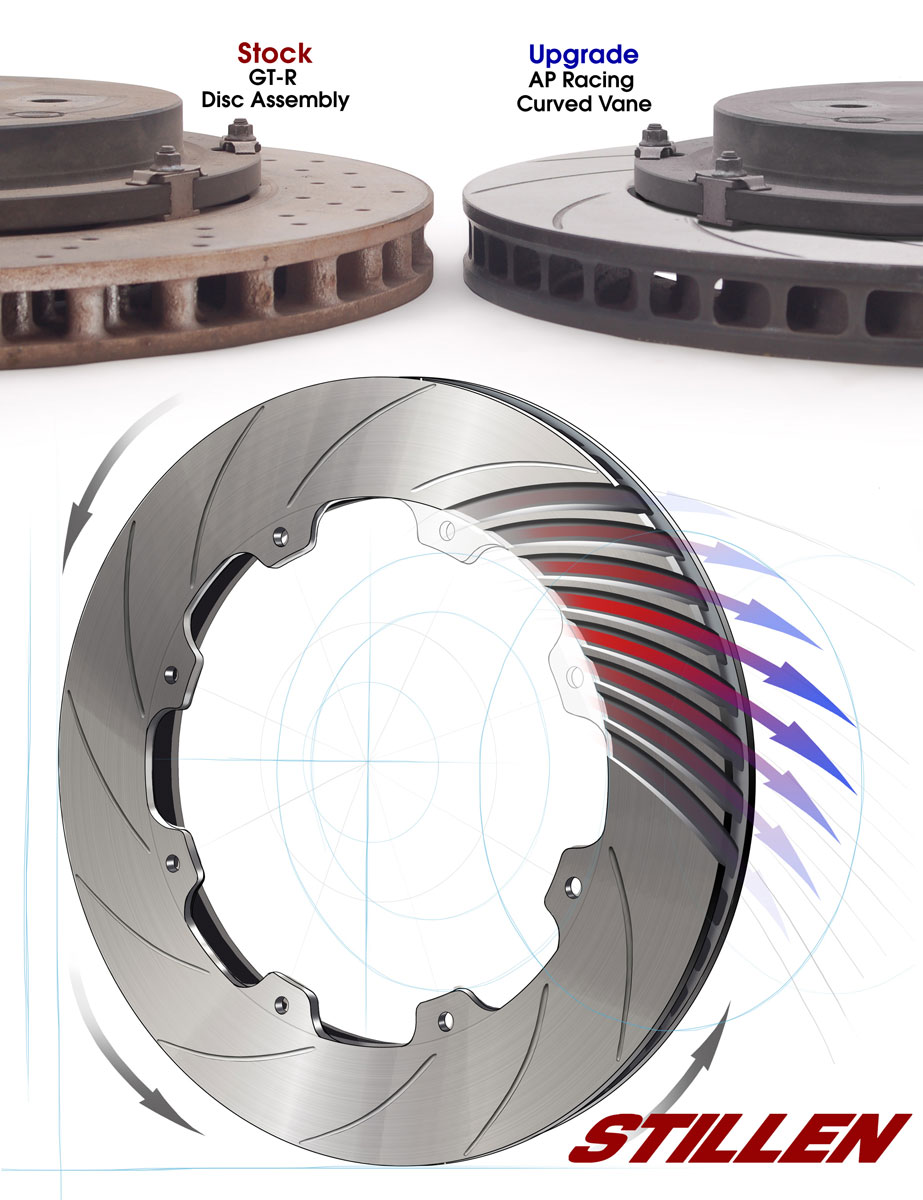

Not all iron is created equal, and STILLEN rotors are produced using an alloy that offers more efficient thermal transfer characteristics and features bigger, better flowing cooling vanes to create a rotor with superior cooling characteristics, but these added features and the use of more expensive materials does increase cost. As a result of cost-saving concerns, typical factory rotors do not benefit from the design elements and use less expensive alloys that lack the heat dissipation characteristics found in STILLEN brake rotors, making a set of Performance Replacement Brake Rotors an especially effective upgrade.

Fighting Fade With Improved Brake Rotors

Aftermarket brake rotors, like those offered by STILLEN, AP Racing and DBA (for example) feature a variety of benefits, thanks to engineering innovations like improved vane design (in the case of vented rotors) as well as cross drilling, slotting and other surface treatments. Many people mistakenly believe that rotors suck air in through the vanes, but it’s actually the opposite. Think about what happens when you have a dirt bike’s rear tire caked in mud, and then blip the throttle. The wheel spins, flinging mud OUTWARDS off the wheel and away. Same idea applies to how air flows through your rotor. Brake rotors draw in air from the center of the hub and the spinning of the rotor flings the hot brake gases outwards through the vanes, cooling the rotor.

It works like this, when your brake rotor turns, it acts as an air pump, drawing in cooler air at the hub and forces that air out, carrying away hot brake gases out through the vents, so it’s worth saying that a rotor’s internal design can play a huge role in its effectiveness.

In the search for improved methods of heat dissipation, some manufacturers of vented rotors have implemented proprietary vane designs to facilitate improved airflow for better cooling of the rotors.

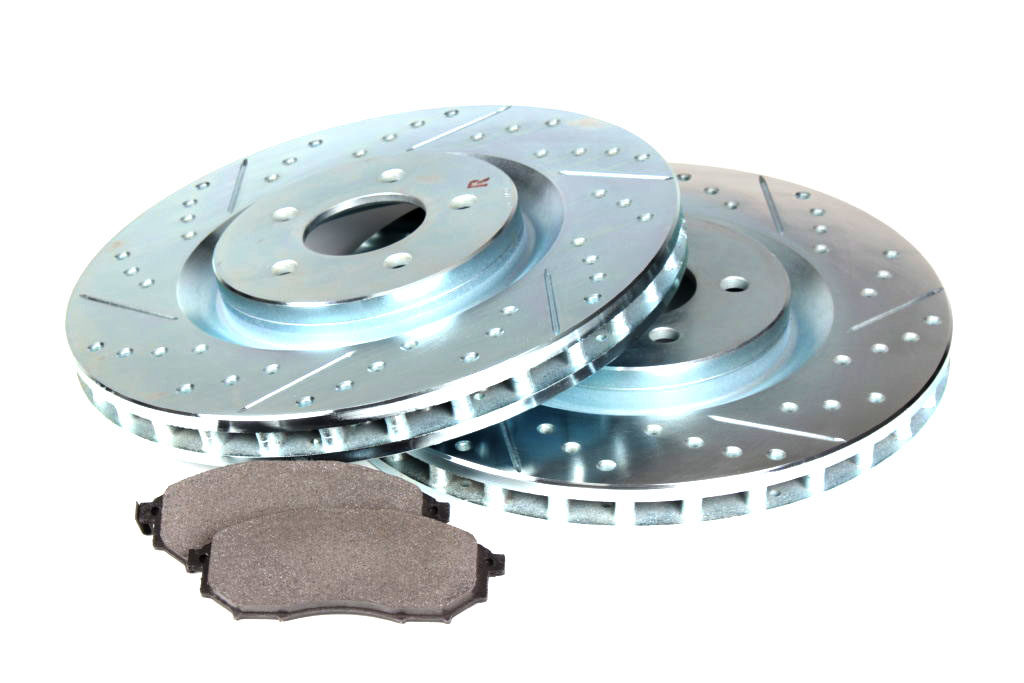

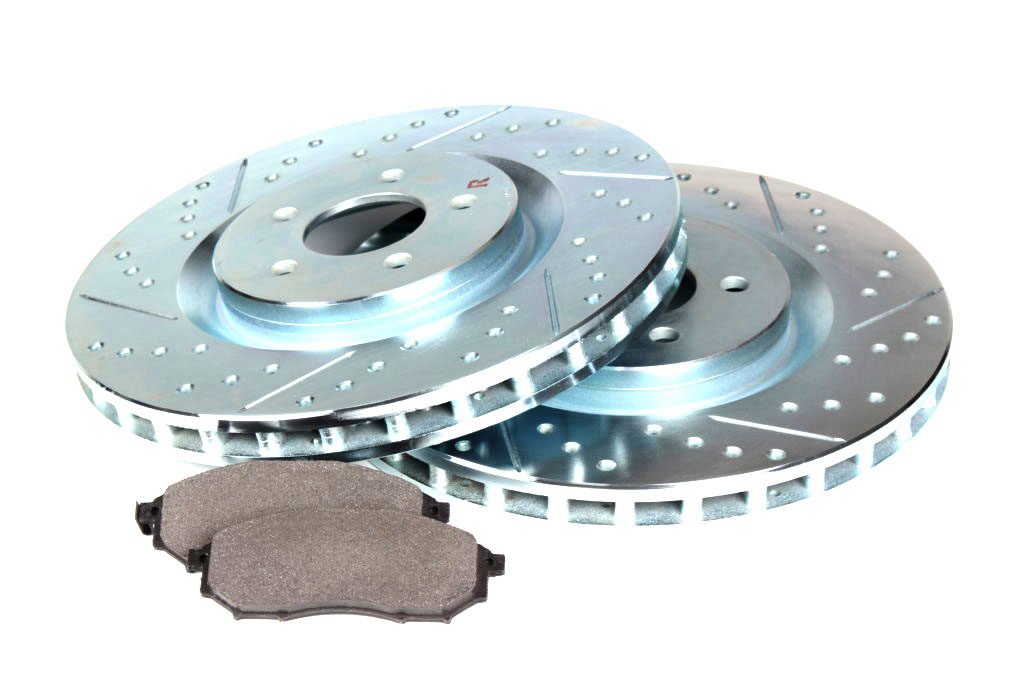

As an added measure of cooling, some have turned to cross-drilling the rotor surface, which provides additional pathways for hot brake gases to escape, thereby enhancing cooling.

Another brake rotor type is the slotted rotor. Most commonly, simple slots are cut into the rotor surface help to optimize the friction surface area while helping to release the gasses that build up between the friction material of the pad and the rotor surface. However, the downside of this rotor type is accelerated wear on the pads, meaning slotted rotors shorten the typical service life of the pads used with them.

Some enthusiasts choose to go with both of these features and opt for Drilled & Slotted rotors, and still others go for the polar opposite and get “blank” rotors for an OEM appearance.

Step Up and Stop Better

With a better grasp of the basics of brake upgrades and the first steps toward better braking for both performance and safety, contact us to order your upgrade today! Do you have more questions about what would be right for your application? Reach out to us at 866-250-5542, at sales@stillen.com or by live chat on our website stillen.com to help you select the product that best suits your needs.

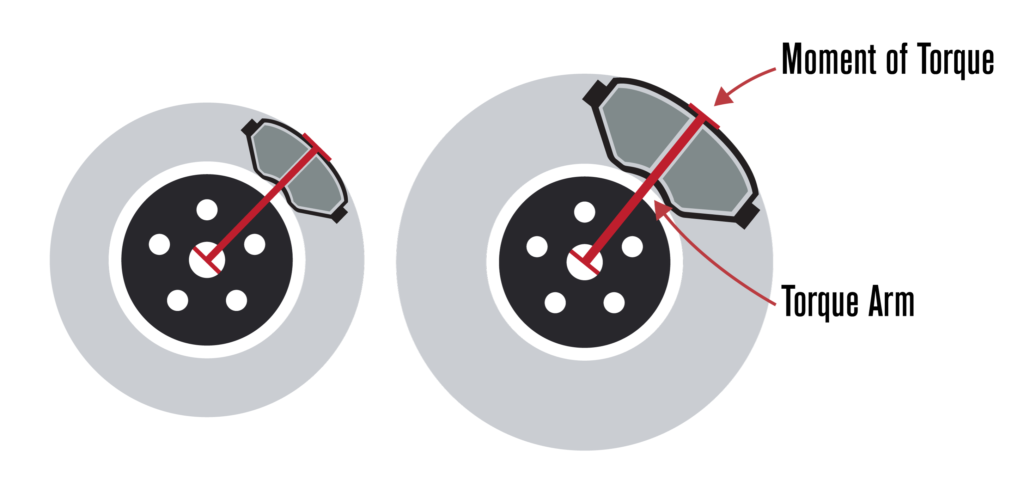

In our next installment of STILLEN University, we’re going to explore brake system upgrades in greater detail and dig into Torque Friction Surface Area in Stillen U, Brakes 301! Check back with us soon!

Contact Us:

866-250-5542

sales@stillen.com

live chat

stillen.com